'I’ve seen more damage caused by wet room mistakes than almost any other bathroom feature' – here's how to avoid making the same errors in your home

Wet rooms may look great, but are not without their risks. Build expert Mark Stevenson shares the most common wet room mistakes and how you can avoid them

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

Wet rooms are one of those features that look deceptively simple. Strip out the tray, tile everything, add a drain and job done. In reality, wet rooms are complex and executed badly, they’re one of the easiest ways to ruin a perfectly good house.

A wet room isn’t just a bathroom without a shower tray. It’s a fully waterproofed space that has to cope with standing water, constant humidity and movement in the structure beneath it. Get any part of that wrong and the water will find the weakest point and quietly cause damage for months or even years, before anyone realises.

I’ve seen more damage caused by wet room mistakes than almost any other bathroom feature, and the frustrating thing is that most of it was completely avoidable. Almost without exception, the failures come down to a handful of common errors which this article explains.

Waterproofing and substrate errors

One of the biggest mistakes is treating a wet room like a normal bathroom. It isn’t. Bathroom tiles alone will not make a room waterproof, no matter how expensive or well laid. Water will exploit any weaknesses, passing through grout and hairline cracks, and damaging the substrate beneath.

Therefore, when installing a wet room, waterproof tanking is essential, but poor installation or even skipping it is surprisingly common. A wet room must be fully waterproofed using a proper tanking system, which can be either liquid-applied or sheet-based.

The tanking system needs to create a continuous waterproof barrier across the floor and up the walls, particularly in areas that get very wet such as walk-in showers. Installation requires attention to detail, with corners and joints reinforced, otherwise thermal movement will cause cracks and leaks.

Problems often occur by not following the specified details or manufacturer's instructions. For example, applying one thin waterproof coat rather than two. Rushing curing times, forgetting primers and omitting reinforcement tape are other common problems. The waterproofing layer also needs to extend beyond the obvious splash zone, and if this isn’t in place water will escape and cause damage to other rooms.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Another surprisingly common mistake is mixing components from different manufacturers. A primer from one brand, a membrane from another, bathroom sealant from wherever is cheapest. The problem is that tanking systems are designed and tested as complete systems, and guarantees will be invalidated if components are switched, or the instructions aren’t followed to the letter.

The importance of getting your substrate right

Wet room systems are only as good as the base they’re applied to, so the substrate is equally as important as the tanking. This base needs to be flat, rigid, clean and dry to prevent any movement and to stop cracks occurring. Timber supports that move and flex under load will cause cracks, so these need strengthening before tanking and ceramic tiling is applied.

When it comes to substrates, even though plasterboard does not belong in a wet room, it crops up far too often. Even moisture-resistant plasterboard isn’t designed for constant exposure to water, so should be avoided. Cement-based tile backer boards or specialist waterproof boards are a better option.

Drainage and gradient mistakes

Drainage is an essential part of any waterproofing system. Tanking can be done perfectly but if water doesn’t drain away, problems will still occur. From a drainage point of view, the gradient of the floor is critical. Water needs to fall gently towards the drain and not be left standing, which would lead to damp patches that never quite dry.

If the gradients are too steep, the floor becomes uncomfortable to stand on and awkward to tile. Getting that balance right is harder than it looks, which is why purpose-made wet room formers are increasingly popular. Forming a gradient manually requires skill, especially over larger areas, so it’s not a job for a DIY approach.

The choice of drainage gulley is another area where problems occur. Linear drains look great and can simplify tiling, whilst central drains are compact and effective for small wet rooms. The mistake, however, isn’t the style, it’s choosing a drain that isn’t compatible for the volume of water it needs to handle.

Modern showers can deliver a lot of water very quickly. If the drain can’t keep up, water spreads across the floor faster than it can escape, eventually creeping into adjacent rooms. The ability to carry out maintenance on a gulley is just as vital, as hair and soap scum will relentlessly build up and cause blockages.

Drain positioning is also often overlooked, but its position will affect a drain's ability to collect water. Placing a drain too close to a wall prevents proper falls from being formed, which in turn impairs how water is collected. The result is compromised drainage, and water that lingers where you don’t want it.

Sealing issues

Once the waterproofing and drainage are in place, tiling is the next thing to get right. Once again, specifications are key to ensure long term performance, but using the wrong adhesive and grout remains a classic wet room mistake.

Standard cement-based products are porous and relatively rigid, which makes them poorly suited to wet rooms. Over time they absorb moisture, discolour and crack. Flexible, waterproof adhesives and mould-resistant grouts are much more suitable, particularly in the shower zone.

Epoxy grout divides opinion because it’s more expensive and less forgiving to apply, but it’s far better suited to a constantly wet environment. It resists staining, doesn’t absorb water and is far less hospitable to bathroom mould.

Poorly sealing is another area where shortcuts cause long-term problems. Internal corners, floor-to-wall junctions and any penetrations through the waterproof layer are all points at risk, and therefore require additional protection. These should never be grouted, and instead a high-quality silicone sealant that can handle movement without cracking should be used.

In a similar vein, pipe penetrations and shower screen fixings are areas where leaks occur if they aren’t properly planned and sealed.

Poor tile choice

Tile choice plays a bigger role than many people realise in wet rooms. Natural stone looks fantastic, but is porous and usually requires sealing to make it waterproof, and to prevent staining.

Highly textured tiles will trap dirt and soap residue, making cleaning harder and encouraging mould growth. Slip resistance is critical, especially when using tiles for wet room flooring. Highly polished tiles may look sleek but are often treacherous when wet. To avoid making a key wet room mistake, always opt for tiles that have an appropriate slip resistance for use in a wet room.

Shop slip-resistant wet room flooring tiles

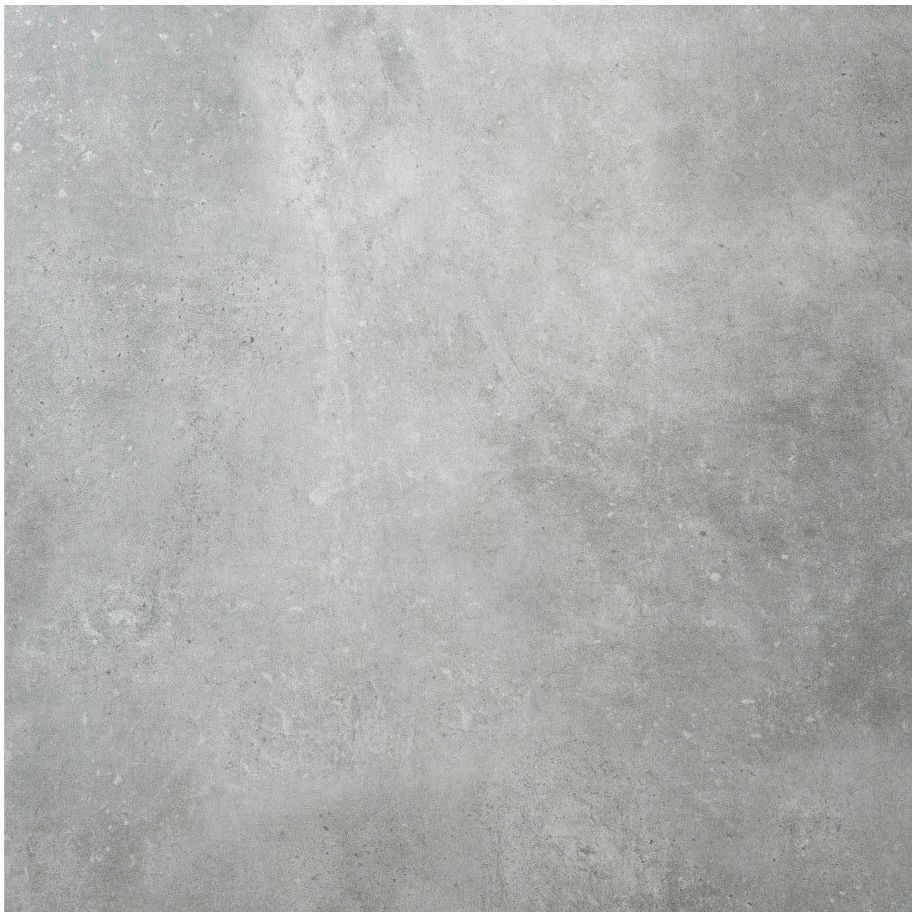

Create a stylish modern wet room with these slip-resistant tiles that resemble concrete

A soothing neutral tile for walls and floors that's suitable for use in wet rooms

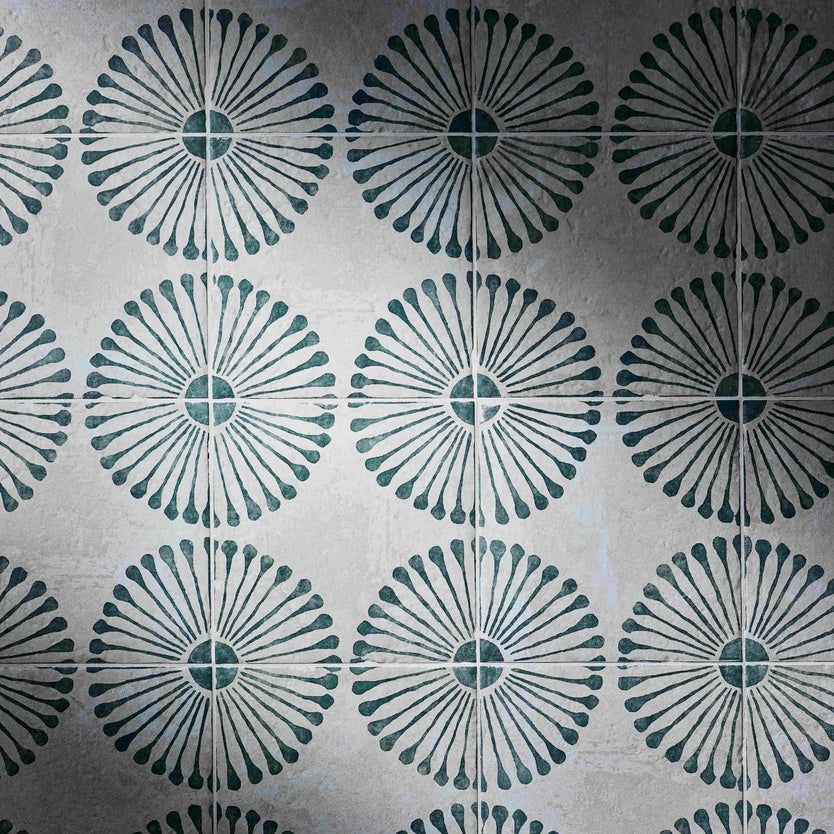

Bring pattern into your wet room ideas with these green and white fan tiles

Design and ventilation flaws

Even a well-built wet room will suffer defects if the overall design doesn’t deal with moisture properly.

Bathroom ventilation is absolutely critical. Wet rooms generate a lot of steam, and without effective extraction that moisture has nowhere to go. Over time it damages paint, ceilings, grout lines, and in extreme cases can even damage substrates.

A background ventilation system such as MVHR, or even a decent humidity-controlled bathroom extractor fan, correctly sized for the room and properly ducted to the outside, will deal with moisture and keep humidity levels within acceptable limits.

As well as the actual extractor, the ducting should be correctly designed and installed. Avoid long lengths as this will restrict extraction rates, and never make the wet room mistake of venting into a loft space instead of outside, as this simply moves the problem elsewhere.

Bathroom heating has a big impact on how a wet room performs as well. For example, cold rooms dry slowly, increasing the risk of mould growth. Underfloor heating is ideal, as it gently warms the entire floor and helps water evaporate more quickly. If underfloor heating isn’t possible, a properly sized towel radiator can help, but it needs to deliver an meaningful amount of heat to have the required impact.

When it comes to wet room design, poor layouts and positioning of fittings should be avoided. Poorly positioned shower heads, insufficient screening and inadequate spacing between fixtures all increase the chances of water escaping and damage occurring later down the line.

My final advice for avoiding wet room mistakes? First, make sure that your bathroom company has experience in installing them. One of the most common assumptions is that all bathroom installers understand how to build a wet room. Wet rooms are specialist installations, and even experienced trades can get them wrong if they don’t follow a system-based approach.

Poor co-ordination and planning when renovating your bathroom is another recurring mistake, and late changes to plumbing or electrics often mean new penetrations through tanked areas, increasing the risk of failure.

And finally, wet rooms aren’t maintenance-free, so the maintenance regime is just as important as the actual installation. Drains need regular cleaning, sealant eventually needs replacing, and grout lines should be periodically checked.

Ignoring small issues almost always leads to bigger problems, so the sooner these are caught and corrected the less chance there is of wet room mistakes causing damage to your home.

Mark Stevenson is a construction professional with almost 35 years’ experience across housebuilding, timber systems manufacturing and bespoke residential development. He is the owner of Elsworth Projects Ltd, a consultancy specialising in the project management of bespoke self-build homes.

Previously Managing Director of Potton and former Chair of NaCSBA and the Structural Timber Association, Mark is widely recognised for his specialist knowledge of timber construction, land finding and appraisal, and the construction of self-build projects.

Alongside his professional career, Mark is a skilled joiner, hands-on renovator and serial self-builder. He regularly shares his knowledge at Homebuilding & Renovating Shows and coaches self-builders.