Staircase Design: Size, Materials, Regulations and More

Coming up with a staircase design can seem daunting given the size and impact of this feature — fear not, our guide takes you through every step

Despite the central position stairs often have in a house layout and their size – not to mention the practical role they perform – staircase design is often not given enough thought, planning or importance.

Need more advice or inspiration for your project? Get two free tickets to the Homebuilding & Renovating Show

Great staircase design should take into account several important factors — we cover them here to ensure your design is a success.

You must carefully plan out every detail of your new staircase design, including its size, configuration and materials. It is also crucial that the final design meets the current requirements of the Building Regulations.

Our ultimate guide to staircase design encompasses all the information you need to ensure you are meeting the relevant regulations, as well containing advice on the best size, location, style and layout for your staircase, as well as the various materials to consider. Plus, if you are wondering who will build and fit your staircase, we've got that covered too.

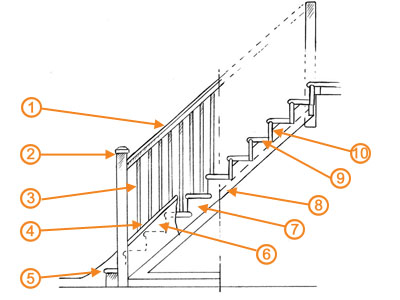

Finally, the technical jargon used to describe stair parts can be tricky to understand— so we’ve included a handy diagram to help.

Staircase Building Regulations UK

When it comes to staircase design and the Building Regulations you should familiarise yourself with Approved Document K.

Staircases have the potential to be safety hazards if not designed properly. If you are buying from a staircase specialist they will be able to advise you — as will your architect or builder.

- Staircases should have a maximum rise of 220mm and a minimum going of 220mm

- They should have a maximum pitch of 42°

- Flights should have a handrail on at least one side if they are less than one metre wide and on both sides if they are wider than this

- Handrails on stairs and landings should have a minimum height of 900mm

- No openings of any balustrading should allow the passage of a 100mm sphere

- A minimum of 2,000mm of clear headroom is required above the pitch line

- For further Regulations see Approved Document K (available to buy from planningportal.co.uk)

Staircase Design Terminology

Where Can I Get a Staircase Design?

There are a couple of different routes you can take to get a staircase design.

Staircase specialist: If you decide to buy your staircase through a specialist staircase company it is likely they will be able to guide you when it comes to a design, taking your through your configuration and material options and coming up with several staircase design options.

Architect: You could ask your architect or house designer to come up with a design. This is actually a good route as they will fully understand the layout and look you are hoping to achieve.

If you are using a package company, such as a timber frame specialist, the staircase design will often be included.

A joiner: An experienced joiner or carpenter should also be able to design and fabricate your staircase. This is often a more affordable option than using a staircase specialist. You could also come up with your own design and take it to a local joiner.

Staircase Sizes Explained

Staircase size should be the very first thing you consider when it comes to developing your staircase design.

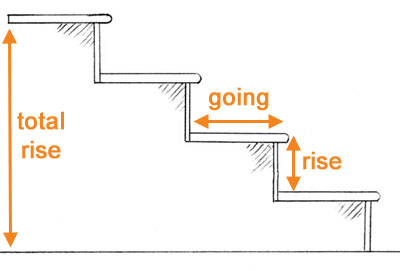

To calculate staircase size, begin by measuring the total rise. This is the measurement from the finished floor below to the finished floor level above.

You can then calculate the number of risers required. To stay within Building Regulations, a domestic staircase needs a rise of between 190mm and 220mm. Standard risers are around 200mm, so aim for this.

The average rise is 2,600mm, which divides easily into 13 200mm risers, or steps.

You can now calculate the number of treads. In general you will need one less tread than the total number of risers.

Next, work out the ‘going’. This is the measurement from the face of one riser to the next.

To comply with the Regulations, the minimum going should be 220mm, whilst the pitch of the staircase should not exceed 42°.

When it comes to staircase width, there are no restrictions as such, but standard flights measure 860mm, and for a main staircase it is agreed that a width of between 800mm and 900mm works best.

A minimum staircase width of 600mm is recommended for secondary staircases.

The Best Place For a Staircase

Every home will have different requirements when it comes to staircase design and so the position of your staircase should be based on your own layout.

In general, the best place for the base of a staircase is viewed as being somewhere near to the front door. It is also preferable not have to cross another room to reach the stairs from the front door. In fact, this is vital if there is a third storey to the house, as the stairs will have to act as a fire escape route.

Consider the way in which your new staircase design will work with the natural light entering your home — avoid positioning the new staircase in such a way that it will block any flow of light.

Staircase Design Configurations

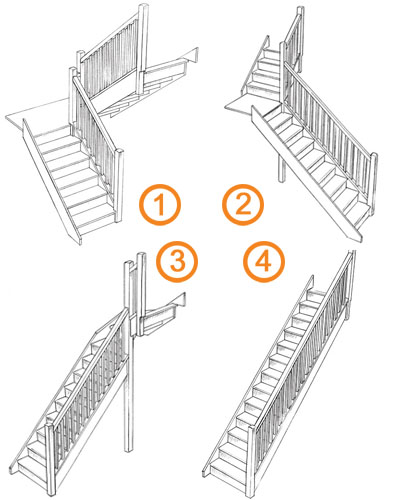

Straight staircases are simple to design and fit – and affordable – but they are not always the best option — sometimes they don't fit or simply won’t work with the interior design scheme.

In these cases, you will need to think about alternative ways that your staircase can get you between floors. The most usual way to do this is by incorporating one or two, or a series of, 'turns'.

When turns are required in a staircase, the simplest option is to split the flight in two and connect them with a 90° quarter turn landing. If you were to use a 180° turn it would be known as a half landing.

Steps that turn corners whilst climbing are called ‘winders’ and are often used to navigate 90° turns.

A turn consisting of three winders is known as a ‘kite winder’. These are often used at the top and bottom of flights to get round corners.

While spiral staircases can be a useful feature where space is very limited, bear in mind that they are often better as secondary staircases as they are hard to get large items such as furniture up and down.

Staircase Design: Your Questions Answered

With staircase design being such a crucial element of the home, it is only natural to have questions surrounding how to achieve the best design for your needs. Here, we answer some commonly asked staircase questions.

Q: How can I incorporate storage into my staircase?

A: Staircases with storage are a great way to make the most of available space. Definitely one up from the understairs cupboard, this bespoke staircase by Bisca incorporates a run of cupboards made from solid wood, combined with a toughened low-iron glass balustrade and stainless steel rails.

Q: I want an extra wide staircase — what do I need to know?

A: Wide staircases can really add wow to an interior design scheme. An extra wide staircase will usually need to be custom made, so this is your opportunity to talk about proportions and scale with your designer or supplier. The materials you choose for the staircase will also have an effect — consider combining solid stone or concrete treads with lighter balustrade materials such as wire or glass.

Q: How can I update my existing staircase cheaply?

For a speedy and inexpensive transformation, consider stair stickers or paint. If you plan on painting your stairs, make sure you use a product designed for that purpose.

Q: Are stair runners a good idea?

A: Stair runners are basically strips of carpet slightly narrower than the flight — bound at either side. They are a great way to really bring a staircase to life, add character and instantly update existing staircases.

Q: Which staircase lights are best?

A: Consider using dramatic oversized pendants or a chandelier over the staircase for maximum wow factor — or consider concealed LEDs to highlight its form — or perhaps a combination of the two?

Q: What is the best way to use space under stairs?

A: The space under your stairs can actually be really useful. Consider fitting custom made cupboards or shelving to gain extra storage.

It also makes the perfect spot to squeeze in a home office and who doesn't need more home office space these days?

Q: How can I light a dark staircase?

A: Using rooflights or a lantern above your staircase will ensure it is flooded with natural light. The light brought in from above is much brighter than that introduced by standard windows.

A sunpipe or sun tunnel is another useful way to bring in natural light.

Check out more inspirational staircase ideas.

Staircase Lights

In some situations it can be hard to pull in natural light to staircases, particularly where they are located in the centre of the house away from any windows.

Yet, even in gloomy spots of the house there are usually ways to draw in light to your staircase design. Methods to consider include:

- Fanlights above doors, both internal and external, to bring light into the base of the staircase

- A rooflight or lantern located directly above the stairwell

- A lightpipe — a useful way to bring light to staircases in terraced homes or where space is tight.

- A full-height or large window located on a half-landing or at the top of the staircase

You should also think about how you will use artificial lights to illuminate your staircase. Not only is it necessary on a practical level, but lighting can also be used to highlight a staircase's design, really bringing its form and smaller details to life.

At the absolute minimum, include lighting at the top and bottom of the staircase – controlled by a two-way switch.

You might also like to consider using LED lights set into the string, handrail or even the stairs themselves — a fantastic way of showing off your new flight.

Uplighters and wall-washers will add a whole new dimension to your stairwell as a whole — whilst a dramatic pendant hanging towards the top of the staircase will really add wow factor.

(MORE: Clever Lighting Design Ideas)

Wooden Staircases: Which Timber?

Wood is a versatile material that is a brilliant choice when it comes to staircase design.

Wooden staircases for traditional homes tend to be characterised by their substantial nature, rounded stair nosing, turned balusters and carved newel posts. However, timber can also be used in contemporary staircase design where it is often seen in the form of chunky wooden treads that cantilever out from a wall.

Timber combines well with glass and stone well too.

At the cheaper end of the market lie softwoods such as pine and hemlock, both of which are brilliant for staircases. Hardwoods such as oak, walnut and ash will be more expensive but offer a very durable and beautiful finish. Some people combine different timbers, using a hardwood for the treads and a softwood for the balustrade.

Pros: Wood is strong, versatile, easy to work with and has a timeless look.

Cons: Very few, hence it being such a popular material. Though dark and heavy wood can, in some cases, be overbearing when used for such a central feature.

Costs: The cheapest option is engineered pine or plywood — ideal for a fully carpeted staircase and painted balustrading. These can be bought from around £500. Next up is parana pine, readily available and fairly cost-effective. This is often combined with hemlock, a good choice for balustrading due to its stability. Hardwoods, such as beech, ash and oak, are more expensive, varying from two times the cost of softwood up to five times the cost.

Glass Staircase Design

Not only do glass staircases allow light to flow easily both between rooms and levels in a house, but they also add a touch of contemporary glamour.

Pros: It’s strong, being made up of two or three layers laminated together. Perfect for contemporary interiors.

Cons: Acrylic can be prone to surface scratches and as a flammable material cannot be used for staircases that will be fire escape routes.

Costs: They rarely come cheap, particularly if buying from specialists. The key to a low-cost yet striking staircase is to combine materials and be clever when choosing your supplier. Having a local glassworks make panels for your balustrading before combining them with a softwood staircase made by a joiner, for example, will work out to be cheaper than going to a specialist.

Metal Staircases

Metal staircases have now made the transition from being seen as purely industrial features, to the home. They are less heavy in their appearance than timber.

Pros: Perfect for spiral or straight flights, they look great paired with glass balustrades or even wire mesh or tension wires

Cons: Badly designed metal staircases can look overly industrial

Costs: Components can now be bought off the shelf, with full timber and metal staircases coming to as little as £500-600

Stone and Concrete Staircase Design

Stone staircases, or those made from concrete, can be traditional – think grand sweeping stone flights – or contemporary in the form of industrial-style simplicity. Concrete stairs are usually supplied precast in sections to be assembled on site.

Pros: The perfect way to create a sense of solidity

Cons: Expensive. May have to wait a while for them to be made

Costs: Variable. They can be expensive, starting at around £10,000. An alternative is to clad existing stairs with stone panels

Where to Buy a Staircase

Unfortunately, buying a staircase is not a simple case of walking into a staircase shop and pointing to the one you want.

It is often the case that the striking staircases that grace the pages of magazines have been custom-made rather than bought off the shelf, designed by the house designer or architect, or sometimes by the owners themselves. However, there are specialist staircase companies out there who will also design and make a staircase.

Those aiming to stick to a budget are well advised to ask a local joiner – or the joiner already working on their project – to help them with a design.

Once you have a design it is entirely possible to buy a staircase from a DIY warehouse or timber merchant – assuming the sizes you require are fairly standard – and then customise it yourself with the addition of a decorative handrail, stair paint or even a distinctive runner.

It is also possible now to develop and order staircases online. Companies such as Stairbox allow you to build up a design using their 'Online Designer' and add the parts required to your basket as you go.

Staircase Terminology

H&R often gets asked how some homeowners seemingly get away without having balustrades. The simple answer is, we might occasionally photograph a house before it gets a completion certificate. We emphasise that staircases are one area where you should never compromise on safety.

Going The horizontal distance between one step and the next, measured from the nosing to the nosing. Building Regs specify a minimum distance of 220mm to a maximum of 300mm.

Nosing The edge of the tread which projects beyond the riser.

Rise The vertical distance from the top of the tread to the top of the next one. Building Regs specify a minimum distance of 150mm to a maximum of 220mm. The total rise is the vertical distance from the floor to the floor of the level above.

Riser The board that forms the face of the step.

Tread The top section of an individual step on which you walk.

Balustrading Describes the combination of the spindles, handrail and newel posts on a staircase. Often it is these elements which give the staircase its character — they can transform an off-the-shelf flight into something special. Timber, glass, metal and even stud walls can all form balustrading.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Natasha was Homebuilding & Renovating’s Associate Content Editor and was a member of the Homebuilding team for over two decades. In her role on Homebuilding & Renovating she imparted her knowledge on a wide range of renovation topics, from window condensation to renovating bathrooms, to removing walls and adding an extension. She continues to write for Homebuilding on these topics, and more. An experienced journalist and renovation expert, she also writes for a number of other homes titles, including Homes & Gardens and Ideal Homes. Over the years Natasha has renovated and carried out a side extension to a Victorian terrace. She is currently living in the rural Edwardian cottage she renovated and extended on a largely DIY basis, living on site for the duration of the project.