Want to know how to cut a hole in wood? Experts reveal there’s more than one way to do it. We help you choose the right one

Discover the top tools and techniques for cutting holes of all sizes, from small to large, to achieve your desired finish

Knowing how to cut a clean, precise hole in wood is a skill every DIYer should have in their toolkit. Whether you’re constructing a stud wall, fitting shelves, or threading cables through cabinets, many DIY projects require creating holes of the correct size.

To ensure success, you’ll need to invest in the right tools and employ the appropriate techniques. The best cordless drills and the correct drill bit will go a long way in ensuring a precise clean hole.

Here, we take a close look at the tools – and how to use them – to cut small, large, and irregular holes for a successful project.

Scott Godfrey is a UK-based master carpenter and joiner at Black Hammer with 20+ years’ experience from bespoke cabinetry to large-scale builds, making him ideally placed to advise on wood drilling and hole-cutting.

Cutting small holes in wood

Small holes in wood are often used for dowels to join sheets of wood, pilot holes for screws, or to pass small cables through. A quick, simple way to make small holes is to use a wood drill bit. A standard wood drill typically comes in sizes up to 10mm. To drill a small hole in wood, simply select a suitable-sized drill bit. Common sizes for wooden dowels used in furniture and shelving are 6mm, 8mm, and 10mm. Mark the drilling spot, place the bit tip on the mark, ensure it is at 90 degrees, and start slowly before increasing speed.

Scott Godfrey, Construction trade consultant for Black Hammer, shares an alternative option, “For clean, accurate small holes in visible work, use a sharp brad‑point bit (like this Bosch Professional Brad point from B&Q). Its centre spur stops wandering, and the spurs score the fibres to leave a crisp rim.” He continues, “Mark the centre, clamp the work, and support the exit with a sacrificial backer to prevent tear‑out. Start square, use steady pressure, and ease off as the point is about to break through.”

However, successful hole cutting relies not only on the tool but also on the right technique, explains Godfrey. “Adjust speed and feed to the material.” He adds, “Softwoods tolerate higher speeds, while dense hardwoods and laminates prefer a slower speed and lighter feed to avoid burning or chipping.”

He adds, “On veneered or melamine panels, tape the face, score the layout with a knife, and always drill from the show face into a backer. For multiple holes, use a depth stop for blind holes and a simple jig or guide to maintain consistent spacing."

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Eric Hargreaves has dedicated 40 years to mastering the home improvement industry, building a reputation as one of the most experienced and trusted professionals in the field. His career spans everything from traditional renovations to cutting-edge design and build projects.

Try these tools to cut holes in wood

This wood drill set features five different-sized bits ranging from 4 - 10 mm with a centre point for precise drilling. Ideal for drilling into softwood, hardwood, plywood and chipboard.

A set of 11 high-quality hole saws with enhanced tooth design for fast and smooth cuts.

A dual-base trim and plunger router, ideal for cutting holes of any size and shape. Includes an adjustable side fence for accurate, straight cuts, with a max cutting depth of 60mm.

4 Tools to cut large holes

There are several options for cutting larger holes in wood. These are the ideal choice if you are looking to cut holes larger than a standard wooden drill bit can. Here, we look at the different tools you can use and reveal what they are typically used for and what sizes they usually cut.

1. Auger bits

These look similar to a standard drill bit, but their design has a few subtle differences, as Godfrey explains: “Auger bits have a screw point and a deep spiral that pulls the bit through, clearing chips efficiently.” He adds, “They are typically used for deep, straight holes in studs, joists, and beams where you need reach and good chip ejection, such as services and fixings.” These are typically available in sizes up to 32mm, like this Meccion Wood Drill Bit.

Godfrey explains what they are best for, “They are about depth and efficiency rather than producing the widest or neatest diameters on a show face.” He adds, “Use a slower speed in dense hardwoods and reduce feed as the screw point approaches the exit to limit breakout. Support the far side with a backer if you can, or stop short and finish from the other face for a cleaner edge.”

2. Spade drill bits

“Spade bits are flat paddle cutters with a centre point, designed to remove material quickly”, explains Godfrey. “They are typically used for fast through holes in framing and other hidden locations, where a crisp rim is not required.” Spade bits like this DEWALT Extreme Flat Wood Drill Bit 9 Piece Set from Amazon range in size from 12mm to 32mm.

He continues, “They can cover larger diameters than common small‑hole work, but they tend to tear fibres, especially in plywoods and laminates.” To get a cleaner result, Godfrey says, “Clamp a backer, tape the face, and slow down for the last few millimetres. For visible work, step over to a Forstner or hole saw to get a clean rim and reduce sanding.”

3. Hole saws

“Hole saws are cylindrical saw cups mounted on an arbour with a pilot bit, used for clean circular cut‑outs in sheet goods and thin timber,” shares Hargreaves. “They’re the go‑to for locks, pipe penetrations and downlights, and they cover a broad span of diameters with changeable cups.”

Hargreaves explains the best way to use a hole saw. “Slow the drill as the diameter increases, keep the saw square, and clear dust regularly to avoid burning.” He adds, “Tape the face, clamp a backer, and stop as soon as the pilot breaks through so you can finish from the other side for a neat edge.”

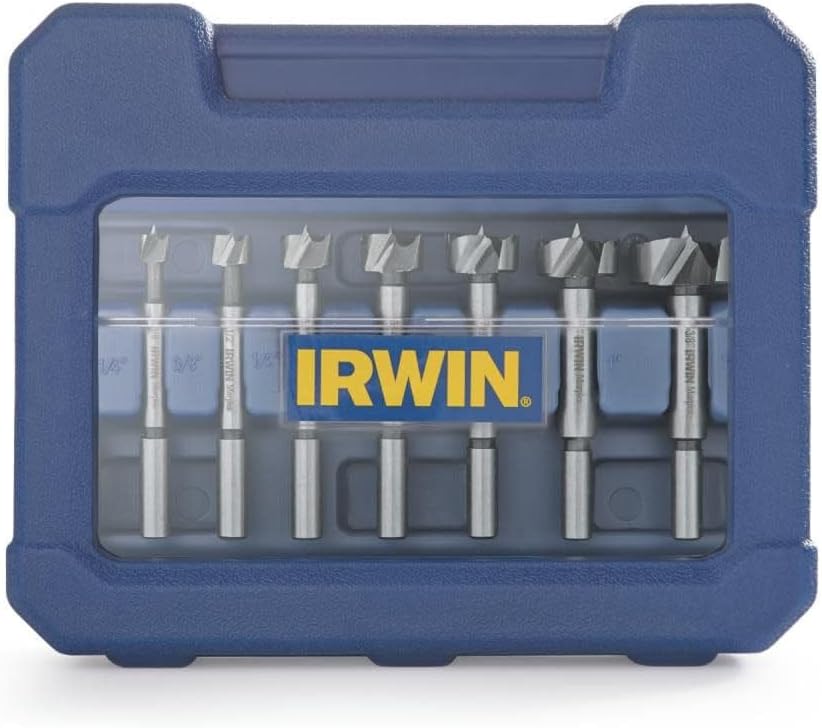

4. Forstener bits

Forstener bits (like this 30mm Forstner Bit Wood Drill Boring Hinge Hole Cutter from B&Q) are slightly different to other bits, explains Hargreaves, “Forstner bits cut very clean, flat‑bottomed holes guided by a rim rather than a long point, so they excel in cabinetry and furniture where the edge needs to be crisp.”

They are typically used to create recesses for hinges and dowel holes. Hargreaves continues, “They let you overlap holes, bore partial depth, and work close to edges with control.”

To use a Forstener bit, Hargreaves says, “Use lower speed and firm support, ideally with a drill guide or drill press for accuracy and repeatability. Back the work, peck to clear chips, and lightly chamfer the edge if the hole will be touched or finished.”

Shop tools for cutting a hole in wood

With over 20 years of experience in the building sector, Mark led Build & Plumb’s expansion into online marketplaces. Over the years working for Build & Plumb Mark has developed a wealth of knowledge surrounding building and renovating.

How to cut round and irregular shape holes

There are a few options for cutting large and irregularly shaped holes. Godfrey explains a popular option for large round holes, “A router with a circle jig (like this Milescraft 1219 Circle Guide Kit from Amazon) or a template gives very clean, repeatable holes and arcs, provided you use a sharp cutter and take shallow passes rather than trying to remove all the material at once.”

To help ensure a clean hole he adds, “Clamp the work firmly, guide the router smoothly, and use dust extraction because routers generate fine chips.”

Irving shares his thoughts, “A router can also be used to cut non-round holes in wood, using different wood cutting jigs.”

For irregularly shaped holes, like countertop holes for sinks, Irving says, “A jigsaw can be used for cutting both large round holes or irregular shapes in wood.” He adds, “These saws have fine-toothed blades that are good for cutting around outlines of shapes. A jigsaw takes more concentration and control than a hole saw, as you will have to move slowly to ensure your cut is precise.” Try this Makita DJV180ZX LXT Cordless Top Handle Jigsaw from Amazon to cut holes and shapes.

FAQs

What is the largest commonly used wood drill bit size?

Hargreaves says, “Ten millimetres is a common everyday size for fixings and hardware.” He adds, “But 'small' in practice runs up to the top end of what you’d comfortably do with standard bits before switching to spade, Forstner, or a hole saw.”

Hargreaves adds more definition to the term small, “I treat anything needed for screws, plugs and light fittings as small, and step up to the next tool family when the hole needs more control or cleanliness.” He adds, “If the face is on show, I’ll choose the bit style that gives the neatest rim and drill from both sides using a pilot to keep the hole centred.”

Should I drill into wet wood?

Yes, you can, but it's not advised for a number of reasons, as Irving notes, “It’s typically advised against as the wet wood fibres can clog together, increasing friction and making the drill bit feel like it’s sticking.”

He adds, “Heat and friction when drilling can lead to worn and blunt drill bits. Furthermore, when the wood dries, it can shrink or warp, which leads to misaligned holes and problems with structural integrity”.

Should you lubricate drill bits before drilling?

Lubricants are not commonly used when drilling into wood. Irving explains why, “Lubricants, like cutting oil, can stain wood and cause problems when painting or staining wood after drilling.” He adds, “Furthermore, the oil can even cause the wood chips to clog in the grooves of the drill bit and ruin its effectiveness.”

If you are struggling to drill wood, Irving suggests a suitable alternative: “Use a small amount of wax, like beeswax, on your drill bit to prevent it from sticking when drilling. Wax can act as a dry lubricant to prevent staining or clogs, whilst reducing friction”

If you are fitting a kitchen worktop or fitting a kitchen sink, there’s a good chance you will need to trim or cut a hole in a worktop. If you’re thinking of fitting a new bathroom sink in a vanity unit, check out our bathroom sink ideas for insight and inspiration.

Steve Jenkins is a freelance content creator with over two decades of experience working in digital and print and was previously the DIY content editor for Homebuilding & Renovating.

He is a keen DIYer with over 20 years of experience in transforming and renovating the many homes he has lived in. He specialises in painting and decorating, but has a wide range of skills gleaned from working in the building trade for around 10 years and spending time at night school learning how to plaster and plumb.

He has fitted kitchens, tiled bathrooms and kitchens, laid many floors, built partition walls, plastered walls, plumbed in bathrooms, worked on loft conversions and much more. And when he's not sure how to tackle a DIY project he has a wide network of friends – including plumbers, gas engineers, tilers, carpenters, painters and decorators, electricians and builders – in the trade to call upon.