Should the UK embrace prefab homes or are they too good to be true?

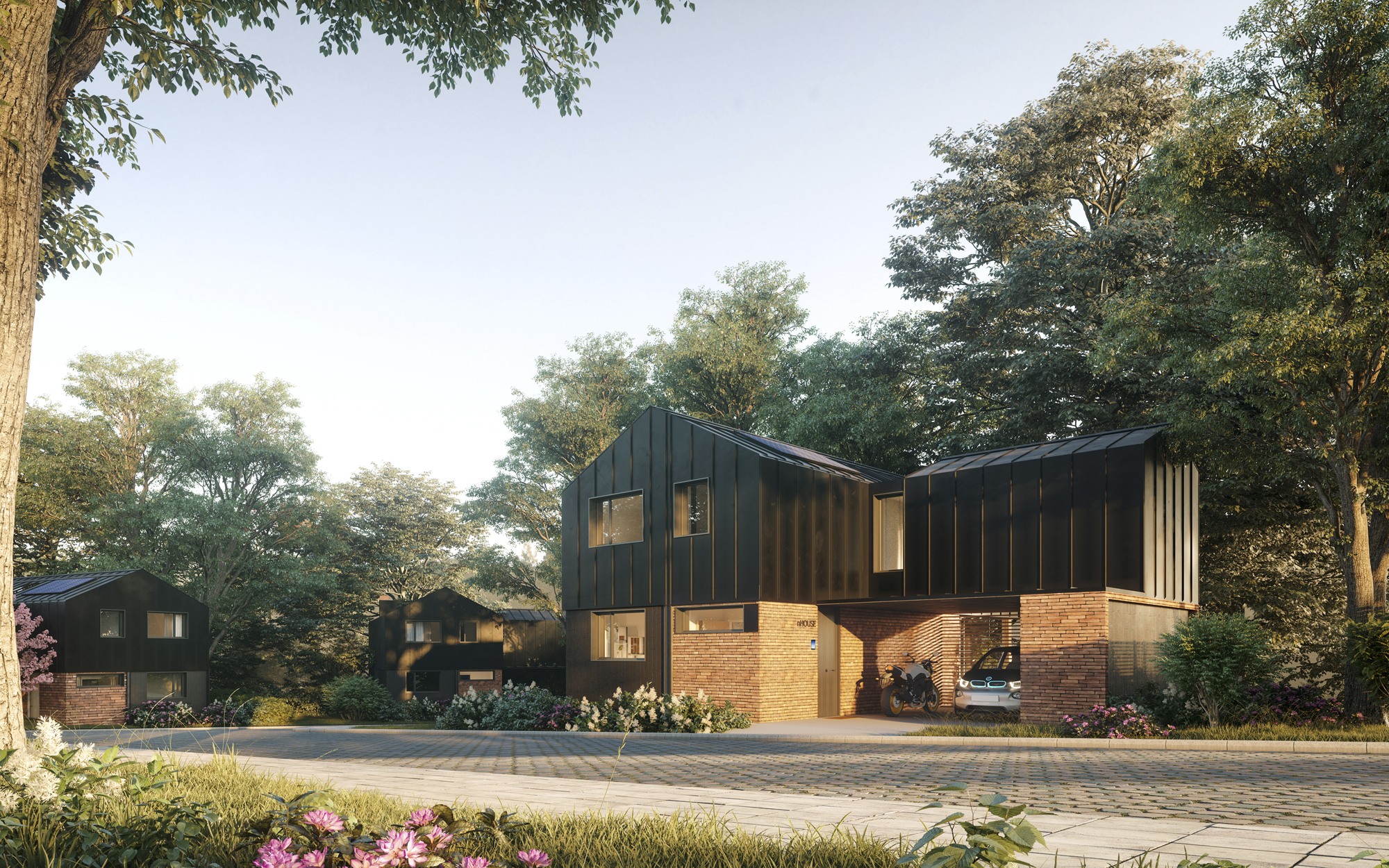

Prefabricated homes promise speed, quality, and sustainability, but can they truly help the UK tackle its housing crisis, or are there hidden challenges?

The UK is facing a housing crisis, with a government target to build 1.5 million new homes by 2029.

Traditional construction is struggling to keep up due to rising material costs, labour shortages, and slow planning approvals. Prefabricated homes are being promoted as a potential solution.

Advocates argue they can build homes faster, with higher quality and lower environmental impact, while the 2025 Modular and Prefabricated Construction Market Report shows the global market is growing rapidly. But sceptics question whether prefabrication can be scaled effectively in the UK.

The debate is growing: should Britain embrace prefabricated housing, or is the solution too good to be true?

What are prefabricated homes?

Prefabricated homes, often called “prefab,” are self-build homes that use offsite factory-made components.

These can include panels for walls, floors, and roofs, or entire volumetric modules that form complete sections of a house.

Once manufactured, the components are transported to the site and assembled, reducing the need for extensive on-site labour and avoiding delays caused by weather or material shortages.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Factory construction allows for greater precision and quality control, often resulting in fewer defects compared with traditional builds.

The global prefabricated construction market

The 2025 Modular and Prefabricated Construction Market Report shows that the global market for prefab construction is growing strongly, driven by urbanisation, sustainability goals, and labour shortages.

The report notes: “Modern methods of construction, including volumetric and panelised prefabrication, benefit from digital design tools and factory-based production, increasing efficiency and quality.”

While this growth is global, the UK has lagged behind, leaving significant potential for domestic homes.

Lessons from other countries

Internationally, prefabrication is well established. In Sweden, 84 per cent of residential homes use prefabricated elements, achieving both efficiency and sustainability.

Japan pioneered modular housing in the 1960s with projects such as the Nakagin Capsule Tower. Singapore has relied on prefab for public housing since 2014 to reduce reliance on foreign labour. In the United States, roughly one in ten new homes is prefabricated, providing millions of Americans with high-quality, affordable housing.

Experts highlight the growing potential of prefabrication. Dr Ramesh Gomasa, Assistant Professor at SR University, describes the trend as “Prefab 2.0”, combining smart technology, automation, and sustainable building materials to create adaptable, high-quality homes.

Architectural critic Dennis Asis adds that modern prefab homes are faster, smarter, and greener eco homes, turning construction into a highly efficient, data-driven process. These insights suggest that, if adapted to UK conditions, prefabrication could address many of the country’s persistent housing challenges.

Benefits of prefabricated homes for the UK

Prefab housing offers several advantages for the UK.

Factory-based production reduces the need for skilled on-site labour - crucial, given that the Construction Industry Training Board estimates the sector will need tens of thousands of additional workers annually to meet housing targets.

Faster construction could help deliver homes more quickly to meet the 1.5 million target, while standardised processes improve quality and energy efficiency.

Self-builders may particularly benefit. Prefabricated systems simplify construction, reduce waste, and allow for modular expansion. Andrew Xue, COO at Offsight, highlights: “Across our network, projects are hitting schedules 15–25 per cent faster, with quality defects reduced by 30–50 per cent.”

Challenges facing prefabrication in the UK

Despite the benefits, challenges remain. Public perception still associates prefab housing with low-quality or temporary solutions, slowing adoption.

The UK’s fragmented planning system and differing local building regulations complicate standardisation for factory-built homes.

Initial factory investments are high, and transporting large modules to some locations can be costly. On top of this, the upfront cost of prefab homes themselves can be higher than traditional builds in some cases, particularly for bespoke or high-spec designs.

Not all international examples translate neatly to the UK. Unlike Sweden or Singapore, the UK’s population is spread across urban and rural areas, which can limit efficiencies.

Dan Campbell, a modular housing analyst, warns: “Factories can play a role, but they are not a silver bullet. Without supportive policies and streamlined planning, prefab alone won’t solve the housing shortage.”

Is prefabrication the solution for the UK?

Prefabricated homes offer a promising route to tackle the UK’s housing crisis, delivering speed, quality, sustainability, and reduced reliance on skilled labour.

However, challenges including public perception, high initial investment, logistics, and regulatory hurdles must be addressed.

With careful policy support, adaptation to local conditions, and integration of modern technologies highlighted in the 2025 Modular and Prefabricated Construction Market Report, prefabrication could become a key part of the solution, though it is unlikely to fully replace traditional construction.

News Editor Joseph has previously written for Today’s Media and Chambers & Partners, focusing on news for conveyancers and industry professionals. Joseph has just started his own self build project, building his own home on his family’s farm with planning permission for a timber frame, three-bedroom house in a one-acre field. The foundation work has already begun and he hopes to have the home built in the next year. Prior to this he renovated his family's home as well as doing several DIY projects, including installing a shower, building sheds, and livestock fences and shelters for the farm’s animals. Outside of homebuilding, Joseph loves rugby and has written for Rugby World, the world’s largest rugby magazine.