How much does a new roof cost? The ultimate guide

Just how much does a new roof cost? Accounting for a large part of any self build or renovation budget, it is crucial to have a clear idea of how much to set aside. Our expert guide is here to help

Exactly how much does a new roof cost? Whether you are building from scratch or are working on a renovation project that is in need of a new roof, this is one of the most important aspects of any home. Not only does it keeps you dry and warm all year, it also contributes a huge amount to the overall aesthetics of your home.

When renovating, extending or building a new home, the roof will be one of the largest expenses — but with so many different types of roof around, pinpointing costs can be tricky.

Here, quantity surveyor Tim Phillips and self build expert David Snell dig a little deeper into the costs of roof types and materials so that you can feel confident when it comes to budgeting for this element of your project.

How much does a new roof cost in 2024?

While some websites might state that the cost of a new roof could be as low as £3,000, is this actually reasonable estimate? It’s worth noting at this point that the cost of re-roofing and/or adding a new roof in the UK has actually increased in recent years due to several factors:

- An increase in material costs: The cost of roofing materials – such as tiles, slates and insulation – has increased significantly over recent years due to a combination of factors that includes increased demand and limited supply, as well as fluctuations in the cost of the raw materials and manufacture.

- An increase in labour costs: The cost of labour has also increased — the construction industry is facing a shortage of skilled workers, which has led to increased wages for those with the necessary skills and experience.

- Increased regulations: The roofing industry is heavily regulated in the UK, and compliance with regulations can add to the cost of roofing projects. In addition, some roofing materials may not be compliant with new regulations, which can lead to additional costs for alternative materials.

- Complex roof designs: The complexity of roof designs has also increased, with more homeowners opting for unique and intricate styles. These designs require more time and labour to install, which can add to the cost of the project.

How much does a pitched roof cost?

The cost of a new pitched roof can vary greatly depending on various factors such as the size of the roof, the materials used, the location of the property and the complexity of the design — for example a dual pitched roof will be more expensive than a simple, single pitch.

As a rough estimate, the cost of a new pitched roof can range from £5,000 to £18,000 or more. However, it’s important to note that this figure is just a rough estimate and the actual cost can be higher or lower, depending on the specific circumstances.

Flat roof costs

This is one of the cheapest types of roof. The construction cost of flat roofs is typically between £1,500 and £5,500. The price may vary depending on the type of flat roof you choose and it will also vary based on its size.

Another factor to consider is the material used for the roof. In flat roof construction, four materials are most often used. Felt, single-ply membrane i.e., EPDM, fibreglass/GRP and also lead.

David is one of the UK's leading self build and plotfinding experts, and a serial self builder who has been building homes for 50 years. The author of Building Your Own Home, David spent decades as a speaker and expert at self build exhibitions such as the Homebuilding & Renovating Show. He has recently finished his fourteenth self build project.

Roof truss costs expained

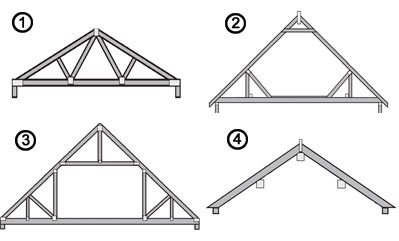

There are many different ways roof structures can be built — some simpler to construct and cheaper to build than others. The structure is a good place to start when looking at costs.

"Roofs are one area of housebuilding which is changing fast," says Mark Brinkley, author of the Housebuilder’s Bible and an experienced builder. "In Victorian and Edwardian times, there was really just one way to build a roof and it's still widely used. But since then we have seen the introduction of many other options."

The type of truss your roof is being constructed with will play a big part in costs, so knowing which are the most expensive and which could save you some money is important.

We asked Gian-Carlo Grossi, managing director of Roofing Megastore how much to expect to pay for each of these types of roof structure:

Fink roof truss costs

Undoubtedly the cheapest form of roofing for most situations, a ‘fink’ truss is identified by having a ‘W’-shaped formation of cross beams and supports within the basic triangle formed by the rafters and the ceiling joists. There are other slightly different forms but they employ the same principles.

The trusses are light and often seem quite flimsy when taken or handled individually. But by being very light allows them to be lifted on to the scaffolding and the roof plate by one man and an assistant, and then stood up and held into place with a temporary batten, nailed across each truss, while the binders and bracings are fixed, locking all of them into a homogenous structure.

An average cost for each truss, assuming a span of around 8m with a 30° pitch, including supply of the necessary binding, bracing and truss clips, would be £56.

It is worth noting that this type of roof is not recommended if you want to use the roof space for more than light storage or on more complex roof shapes.

| 17 trusses with bracings, bindings and truss clips | £1,128 - £1,347 |

| Labour (carpenter plus mate) for one and half days | £548 - £750 |

| Total | £1,676 - £2,097 |

Traditional cut roof costs

A traditional cut roof (also referred to as a purlin and spar roof or cut and pitch) is constructed on site using loose sawn lumber with the timber sizes determined by a set of tables or by the recommendation of a structural engineer. Because the rafters do not have support struts within the triangle formed by them and the ceiling/floor joists, they require some form of support at their mid span between the eaves and the ridge. This is provided by heavy timbers, on each side of the roof, running counter to the rafters and built in, and supported by the end and cross walls of the house.

In cost terms, there is not much to choose between an attic truss and a traditional cut roof. In fact, it can often be hard to tell how an open-attic roof has been built, but it tends to come into its own when the roof shapes are complex.

| Sawn lumber | £2,903 |

| Labour (carpenter plus mate) for seven days | £2,555 - £3,000 |

| Total | £5,458 - £5,903 |

Attic truss roof costs

The huge advantage of the traditional purlin and spar roof was the fact that it provided clear space within the attic that could easily be converted for use as living space.

The attic truss, however, provides that option by doing away with the ‘W’-shaped supports within the main triangle and replacing them with upright supports close to the eaves, together with a cross tie support at what would be ceiling level. Effectively this creates an open space along the length of the roof with sloping ceilings to the occupation section, together with eaves storage.

Not unnaturally, the timbers have to be bigger. And the result is a much heavier truss, which can’t easily be manhandled on to the roof and may need a crane or some other form of lifting assistance. Once they are up on the wall plate their erection proceeds in much the same format as for the fink trussed roof.

An average cost for each attic truss, assuming a span of around 8m, with a 45° pitch (necessary to provide sufficient headroom in the proposed attic), including supply of the necessary binding, bracing and truss clips, would be £163.

| 17 trusses with bracings, bindings and truss clips | £3,284 - £4,918 |

| Labour (carpenter plus mate) for two days | £548 - £750 |

| Crane hire | £385 - £500 per day |

| Total | £4,217 - £6,168 |

Panelised roofing costs

Panelised roofing uses large pre-insulated sheets, laid across roof beams, so works best on simple-shaped roofs. It is more expensive to buy a roof this way, but fitting costs are reduced because the panels are pre-insulated.

Gian-Carlo is founder and managing director of Roofing Megastore and holds a wealth of experience of working within the building materials industry.

Roofing material costs

As well as the roof structure and type of roof you opt for, the materials you choose to cover your roof with play a major role in the costs you will face.

Choosing the correct roofing materials – whether it’s for a new build project or a re-roof – is crucial. It’s important to be aware that there are cheap alternatives on the market. You should also be aware that if you ‘buy cheap, you get cheap’. For example, don’t expect a felt flat roof to last as long as a single-ply membrane flat roof, or for a Chinese natural slate to remain as colourfast over time as a Welsh slate.

That’s not to say that you can’t look for savings on material specification, while maintaining quality. For example, your original roof may have a Welsh slate roof, but the local planning authority may well be amenable to re-roofing it with different types of slate finishes, such as Glass Reinforced Concrete (GRC) slate or a natural slate from other countries.

When you consider that Welsh slate could be as much as £160/m2, you could make considerable savings by switching to Spanish slate, which comes in at a cost of around £60/m2. Conversations around specifications are well worth having, not just from a planning perspective but with your architect, too.

Take a look at our table to get a clearer idea of the quotes you can expect.

| Flat roof | Price per m2 (material only) | Pitched roof | Price per m2 (material only) |

|---|---|---|---|

| Felt | £55 | Double Roman | £32 |

| Single ply membrane | £90 | Eternit tiles | £39 |

| Fibreglass/GRP | £95 | Plain concrete tiles | £49 |

| Lead | £145 | Clay tiles | £58 |

| Row 4 - Cell 0 | Row 4 - Cell 1 | Spanish slate | £60 |

| Row 5 - Cell 0 | Row 5 - Cell 1 | Reclaimed Welsh slate | £75 |

| Row 6 - Cell 0 | Row 6 - Cell 1 | Welsh slate | £160 |

Roof replacement costs

Replacing an existing roof comes with its own set of challenges, some of which can really see costs soar.

The cost of re-roofing a house can range from £6,500 to £20,000, according to its size and complexity. However, opening up an existing roof may uncover rotten timbers, perished felt (which was used predominantly in the pre-1990s, before the introduction of breathable membranes). And timber rafters and wall plates may need renewing, too. The main cost factor will depend on the existing type of roof, whether it’s pitched or flat and the material – flat roof replacement costs, for example, will be very different to pitched.

What should a roofing quote include?

To get a more accurate idea of the cost of a new roof, it’s best to contact a reputable roofing contractor in your area and get a detailed quote based on your specific requirements. Try to make sure they are a member of the NFRC (National Federation of Roofing Contractors) who also have a useful website, where you can search for roofers in your area.

Most roofing quotations will include labour and roofing materials. After receiving a quote for a new roof, make sure it includes the cost of replacing fascias and soffits, as well as new rainwater goods, which again can vary in materials from uPVC at £15/m to £36/m for aluminium. New fascia, soffits and bargeboards are an additional cost. Depending on the type of roof you choose, it will nearly always require insulation so this will need to be factored in, too. It will be a large proportion of the overall cost so make sure it’s included in your quotation, whatever types of roof insulation you are looking at, e.g., £20/m2 should cover the material cost of 125mm Celotex Insulation slab for a flat roof.

Factors that can increase roofing costs

There are several things that have a major influence on the final cost of a roof.

One of the main factors that affects the price of the roof structure is the same factor that impacts on the price in so many other elements of the building: complexity. Consequently, the simpler the shape of roofs, the cheaper their price.

Undoubtedly, moving away from a fink trussed roof to either an attic truss or a purlin and spar roof will add to the costs. But, even so, it provides the opportunity for ‘cheap’ space either immediately or at a later date and is therefore cost-effective in real terms. Thought does, however, have to be given as to how one is to gain access to this additional storey and the knock-on effects, such as the need for fire doors if a third storey is provided.

Other influencing factors to be aware of include:

- VAT on roofing renovation projects: It’s important to note that the VAT rules for renovation projects can be complex, and the VAT rate may depend on the specific details of the project. Therefore, it’s best to consult with a qualified professional to determine the applicable VAT rate for a specific re-roofing project. “If the project is a new build then the VAT can be claimed back through the VAT431 scheme,” advises Andrew Jones from The VATMan Ltd.

- Multiple roof types: If your main roof is pitched and another section is flat, with the covering materials being a mixture e.g., slate/concrete tile and EPDM, then discuss with your builder or roofer. Where the flat EPDM roof adjoins the pitched slate/concrete tile pitched roof, this will require weathering and also the possibility of expansion joints. The materials will move differently over time so make sure this detail is allowed for in the quotation and carried out properly on your roof.

- Complexity of roof structure: Roofs come in all shapes and sizes, e.g., gable, hip, flat, mansard, curved and even jerkinhead. The more complex the construction, whether through complex geometry or a wide range of materials, the more expensive it will be. Complex roofs with dormers, rooflights and maybe even solar panels, for example, will increase the quotation from your roofer, both in terms of material costs and the number of labour days required. A huge variety of materials may require a number of different skilled trades to install them, driving up labour costs.

- Roof removal: Don’t forget to budget for skips for general roofing materials. A large skip can cost up to £400 in London and £280-£350 in the rest of the UK. The removal of asbestos roof tiles is a highly regulated process that must be carried out by licensed professionals who have received specialised training and certification. Allow a minimum of £1,200 for the works. Before any work can begin, a survey must be conducted to determine the location and condition of the asbestos roofing materials. If asbestos roof tiles are identified, a licensed contractor must be hired to carry out the removal process.

- The location of your project: The location of the project will naturally impact on the cost, based on labour prices alone. This always impacts labour costs, with prices being higher in London and surrounding areas, but it’s even more relevant in the current climate with the current elevated fuel costs. Those in remote areas may face higher costs based on travel distance as opposed to postcode. Always try to engage roofers based as close to your locality as possible. If your property is listed or within a protected area (National Park/Area of Outstanding Natural Beauty) you will not only have to add the cost of applying for planning permission but the permitted options are likely to be more expensive specialist materials requiring skilled application, i.e., Welsh Slate.

- Access and provision of specialist scaffolding: Scaffolding will be required around your property for the majority of re-roofing jobs. Analyse your new roof quotation to see if the scaffolding is included in the price. Scaffolding for a typical three-bedroom semi-detached house costs around £2,000 to hire, with permits and licences.

- Specialist skill: If your chosen roofing material (i.e., zinc, thatch, green, or even solar photovoltaic) requires specialist skills to fit it, this will push up the labour costs. Skilled thatchers are expensive and becoming harder to source, which drives cost up even further. Costs can vary dramatically for a thatched roof, depending on where you live in the UK, and can be anything from £1,500 to over £3,000 per thatcher’s square (9.3m2). If your project requires specialist work, this will increase the cost, as their knowledge and expertise is specialist and therefore attracts a premium.

- Features such as dormers, rooflights, etc.: Dormers, rooflights, roof lanterns, sun pipes, etc may require re-weathering with lead, cladding or EPDM. So, ask your roofer to assess whether this is required. For a new roof expect these items to be priced individually on your quotation.

- Additional work for roofers: Your chimney is worth repointing or rendering while the scaffolding is erected. It may also require new lead flashing. Any roof penetration, even Velux rooflights or sun pipes are an access point for water leaks, so get them weathered properly, as this can prove costly in the long run.

- Labour costs: Depending on the size and complexity of the job, you can expect to pay between £25 and £35 per hour for a roofer. If the job is large, you may be quoted a day rate, which will typically range between £200 and £280, depending on your location and the level of expertise required for the project.

Tim Phillips is an experienced senior quantity surveyor and estimator and has worked in the construction industry for over 35 years. He has worked on many varied projects in this time, for corporates, public bodies and private residential clients, managing multi-million budgets. @timphillips71

FAQs

Can you cut new roof costs by taking on some of the work?

You can shorten the time that labour will be on site. With light trusses, getting them up on to the wall plate yourself can save at least half a day’s labour. Sorting out the piles of lumber into sizes and, if possible, uses such as rafters, joists, purlins, hips etc., will save at least a day and possibly more of an expensive carpenter’s time.

Getting the slates onto the roof is a long job and one that the self builder could do. But it’s not easy, although one could save around five days of labour.

Are green roofs expensive?

One type of roof that we haven't looked at here is green roofs. There are three main types of green roof: intensive, extensive and semi-extensive, each with their own pros and cons and price points.

Prices start from £50/m² for a relatively simple sedum roof right up to £200/m² or more in the case of a planted intensive roof. You will also need to factor in possible reinforcement measures that might need to be taken to the walls below.

Check your insurance covers roof replacement

"Whilst not always an avenue you can take, if you’re replacing your roof because it is damaged, we would always suggest checking in with your insurance provider to see if replacement is covered in your policy," advises Gian-Carlo Grossi. "In the majority of cases, full coverage will only apply if your roof was already in good condition and the cause of the damage was an act of nature (such as a falling tree). However, most will still cover at least a portion of your costs as long as the damage was not a result of a long-standing and unresolved issue."

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Tim Phillips is an experienced senior quantity surveyor and estimator and has worked in the construction industry for over 35 years. He has worked on many varied projects in this time, for corporates, public bodies and private residential clients, managing multi-million budgets.

For the past 13 years, Tim has worked on a freelance basis, whilst managing his rental property portfolio. He has extensive experience of undertaking his own full-scale house renovations. He is also a speaker and expert at the Homebuilding & Renovating Shows.