Insulating a Wall: What You Need to Know

Find out the essentials of insulating a wall, with expert advice types of insulation and walls, and how to insulate internally, externally or in the cavity

Insulating a wall, either internally, externally or in a cavity, is an important part of achieving thermally efficient home. Not only is a more efficient home better for the environment but a home where heat loss is kept to a minimum means lower energy bills and increased long-term savings.

The amount of heat a building loses is measured in a couple of ways, including a home's EPC rating where homes are placed into bands A-G, with the A including the most efficient houses. Although the average home is band D, a survey by the PWC Economic Outlook in 2021 suggested that 1/4 of energy bills could be saved (approximately £178) is households upgraded their homes to EPC rating band C.

Another measure is the U value where the lower the value the more heat the house retains. With the release of the 2014 Building Regulations all the elements in the fabric envelope – the roof, walls and floor – need to have virtually the same U value. The maximum U value for walls is 0.3, although in reality you would want to beat that — perhaps down to 0.15.

How Do You Insulate Existing Walls?

If you're looking to insulate a wall in an existing home, working out the types of wall you have will inform the type of insulation required.

If you've got uninsulated cavity walls (most homes after the 1930s have cavity walls and you can drill an inspection hole, or ask a surveyor, to check if it's insulated) then filling the cavity is a sensible step in most cases. You could then in theory boost your performance by adding internal or external insulation.

If it's a solid wall, then your choice is much simpler — it's either external or internal. Scroll below for more information on both.

Comparing Internal and External Wall Insulation

The same figures for thermal conductivity and U values apply to renovation projects as new build. In some circumstances the Building Regulations also require the same standard as for new build. The difficulty is that the walls are already up and less easy to insulate.

Insulating the External Surface

External wall insulation will need some form of external cladding – typically render or timber – over the insulation itself. This acts as weatherproofing and prevents any moisture penetration. The options are limited to rigid foams or wood fibre, which are usually mechanically fixed to the wall, although some can be glued.

The insulating effect is broadly the same as internal insulation, although external insulation has two further benefits:

- It is more continuous, covers a larger area and helps overcome cold bridges

- It wraps the wall and allows the mass of the wall to act as a thermal store. That in turn helps to take the peaks and troughs out of the heating cycle.

Both reduce the heat demands, but external insulation tends to be more expensive than internal insulation.

Insulating the Internal Surface

Internal wall insulation can be applied directly to the wall or in a new – typically timber stud – wall set off from the existing wall. Which one is best will depend on the condition of the existing wall, if it is a solid or cavity wall, and if there is any moisture penetration.

Kingspan and Celotex both offer products that have a moisture barrier that can be applied directly to the wall. Natural insulation can also be applied this way as they allow any moisture to be wicked away. Otherwise, leaving a gap between the wall and insulation ensures that there will be no damp penetration.

A 225mm solid brick wall will have a U value of around 1.7W/m²K and a 400mm stone wall about 1.4. Adding 50mm of rigid insulation will reduce the U value to around 0.4, while 50mm of mineral wool or natural insulation will reduce it to 0.5.

Types of Wall Insulation Explained

Foam Wall Insulation

Rigid polyurethane (PUR), polyisocyanurate (PIR) or phenolic foam are all insulation foams offer similar levels of insulation, with a thermal conductivity of around 0.021 to 0.023W/mK. PIR and phenolic foam have largely taken over from PUR. All are suitable for insulating walls.

Polystyrene is either expanded (EPS) or extruded (XPS).

- EPS has largely been superseded by phenolic and PIR. It is also available as loose grey or white beads for blowing into cavity walls. The grey beads have graphite added which reduces the K value (a measure of the material’s thermal conductivity, the lower the better) from 0.034 to 0.031, and is more expensive.

- XPS This is similar to EPS but with a much tighter, stronger closed cell structure, improving its K value to 0.027. This structure gives it much better compressive strength and water resistance. There are question marks over its environmental credentials due to the levels of energy needed to make it. It is typically used for flat roofs and floors.

Spray foam insulation is another option which uses a mix of liquid chemicals that expand into a solid foam insulating layer.

Semi Rigid Wall Insulation

These include mineral or natural insulation wools, hemp and wood fibre with resin bonding, polyester or other fibres that give a degree of stiffness. Thermal conductivity is generally 0.038 to 0.042W/mK.

- Mineral wool includes both mineral wool and glass wool. These are longstanding products, familiar to us all. Mineral wool is a slightly better insulator than glass wool and slightly more expensive; both types can be used for walls with proper installation.

- Wood fibre insulation is available as wool-like rolls, semi-rigid boards or rigid boards. It is suitable for use as wall insulation.

Any of the rigid or semi-rigid insulators install well in what is a vertical application (the wall).

Flexible Wall Insulation

This is the same as semi rigid but without the stiffening and with the same thermal conductivity. Examples of flexible insulation include sheep’s wool, straw, cotton (often recycled clothing) and quilt materials.

Rigid and flexible insulations need treating in different ways: rigid will stand up on its own, but flexible needs support to prevent it from sagging. Wool or quilt materials can be used but they’re more difficult to install well on a wall than a floor or roof, and some sagging is almost inevitable.

The thermal conductivity figure shows that almost twice as much flexible insulation will be needed to achieve the same U value. For example, a ‘standard’ cavity wall needs 70mm of PUR to achieve the Building Regulation’s maximum U value of 0.30, whereas mineral wool needs 120mm.

Eco Insulation Options

For homes that want to go above and beyond in term of green credentials, eco insulation choices include sheep's wool, recycled materials (such as PET made from plastic bottles), and hemp.

Insulation Advice for Renovators

Solid Wall Insulation

If you're in an area where the outside appearance of your house is governed by planning constraints, or if the house if listed, then you're likely to only have the choice of insulating the inside of the external walls.

Equally if the reverse is true if you're looking at how to insulate old homes and you want to avoid internal changes you can do so by using internal wall insulation.

Cavity Wall Insulation

Installing cavity wall insulation can reduce U values in walls previously without insulation from 1.5 down to 0.5 and below. That is a good thing, but installing it demands careful planning and application so it pays to be aware of cavity wall insulation problems.

Horror stories around cavity wall insulation abound, with some justification. There is no secret about it — some cavities are just not suitable for insulating (for example, if the brickwork is in poor condition). A clean cavity – one free from mortar dollops on cavity ties and from mortar or other debris in the bottom of the cavity – is good to insulate, but a messy cavity isn’t.

The trick is finding out which one you have. The only way is a visual inspection (typically using a small camera) which should be carried out by a competent insulation installer.

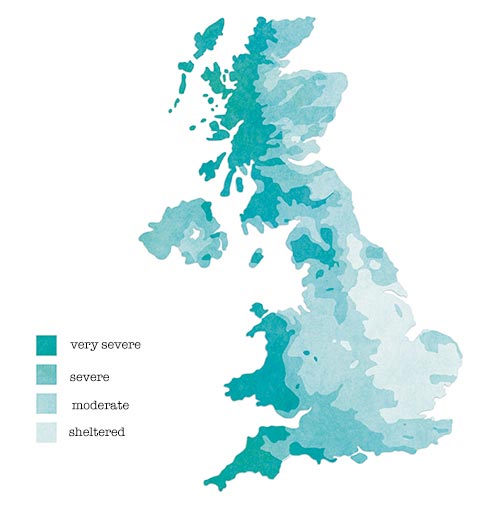

There are stories about north- or west-facing walls being unsuitable for cavity wall insulation due to the driving weather conditions those elevations are prone to. However severe the weather, it is unlikely to penetrate beyond the outer brick leaf, so what happens in the cavity will not be affected by the weather.

However, Building Regulations Part C (5.15) does still refer to a map of the UK (below), published as part of the Regulations, that shows the country according to risk of driving rain, and effectively prohibits full-fill cavity insulation in these areas (for new builds). It’s worth at least raising this with the insulation supplier.

Some older buildings may be exceptions but generally insulating a wall is a given and the only questions are how much and what with? And whatever the decision, insulating the walls will have a dramatic and noticeable impact on energy consumption and comfort.

Insulation Options for a New Build

A U value better than the Building Regulations minimum will be needed to meet the new demands of a SAP assessment. A U value of 0.20W/m²K or better is required and that means either 110mm rigid insulation or 170mm of mineral wool (or other natural wool).

Using rigid insulation will result in only a 10mm reduction in overall wall thickness, as mineral wool can be used to fill the cavity, whereas a 50mm cavity is still needed with the rigid boards. With structural insulated panels (SIPs) and timber frame, the inner leaf of the wall replaces the block skin and is virtually all insulation. This means that the same U value can be achieved with less wall thickness.

A Complete Insulation Scheme

Insulating walls is an important part of achieving a thermally efficient home, where heat loss is kept to a minimum – airtightness is the other key measure.

The key to good insulation is continuous insulation, including insulating floors and even window and door reveals, too. Leave those uninsulated and around half the effect of the wall insulation will be lost.

However, installing 50mm of insulation (plus plasterboard or other finishing material) to a window or door reveal is generally not practical. There are very thin materials, like Proctor Spacetherm, that will do the job. They tend to be very expensive but very effective and useful for these small areas.

Along with insulating a roof, insulating external walls can dramatically reduce the amount of heat lost from the house.

Price Guides to Insulating a Wall

Prices will vary with the type of insulation, manufacturer, supplier and quantity. The main priority is deciding on the right type of insulation for the job, and then finding it at the best possible price. There really are no quality issues and, on a like-for-like basis, one manufacturer’s products are pretty much the same as another’s.

Prices range from roughly £4-13/m² (wall space). For rough budgeting purposes, expect to pay £5-7,000 for internal wall insulation, and £6,000-10,000 for external wall insulation. Visit Insulation Online for a good price list.

How Can I Insulate my Walls Cheaply?

There have been various government grants over the last few years to bring the cost of making homes more efficient, including insulation the walls, a more achievable ambition for UK Homeowners.

Under the ECO (Energy Companies Obligation) scheme any homeowner can now ask whether they are entitled to a free install of cavity wall insulation (it’s no longer income-tested).

The Green Homes Grant, infamously tries to incentivise improving energy efficiency by offering funding to homeowners. Following its closure, the government allocated £320million to the 'local authority delivery' part of the scheme.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Tim is an expert in sustainable building methods and energy efficiency in residential homes and writes on the subject for magazines and national newspapers. He is the author of The Sustainable Building Bible, Simply Sustainable Homes and Anaerobic Digestion - Making Biogas - Making Energy: The Earthscan Expert Guide.

His interest in renewable energy and sustainability was first inspired by visits to the Royal Festival Hall heat pump and the Edmonton heat-from-waste projects. In 1979

this initial burst of enthusiasm lead to him trying (and failing) to build a biogas digester to convert pig manure into fuel, at a Kent oast-house, his first conversion project.

Moving in 2002 to a small-holding in South Wales, providing as it did access to a wider range of natural resources, fanned his enthusiasm for sustainability. He went on to install renewable technology at the property, including biomass boiler and wind turbine.

He formally ran energy efficiency consultancy WeatherWorks and was a speaker and expert at the Homebuilding & Renovating Shows across the country.