What is a tenon saw used for, and how does it differ from other saw types? Here you’ll find the answers to six common questions

If you don’t have a tenon saw in your toolkit, find out why you might need one and what jobs they are good for

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

There are a lot of different saws that can be included in a DIYer's toolkit, but before you add a tenon saw, you’ll need to know what it is used for. It's a specialist saw typically used for woodworking projects, but it also has other everyday uses.

A tenon saw offers more finesse, accuracy and precision than many other types of saws, such as the best reciprocating saws, circular saws, and general-purpose handsaws. Don’t expect to use a tenon saw on most DIY projects, but it's a budget-friendly saw that should be included in your toolkit.

Scott Godfrey has over 20 years of experience in carpentry and joinery, is a master craftsman, and a successful business owner. He has extensive experience in both bespoke and large-scale projects, including luxury home builds and renovations.

Try these tools to help using a tenon saw

1. What is a tenon saw used for?

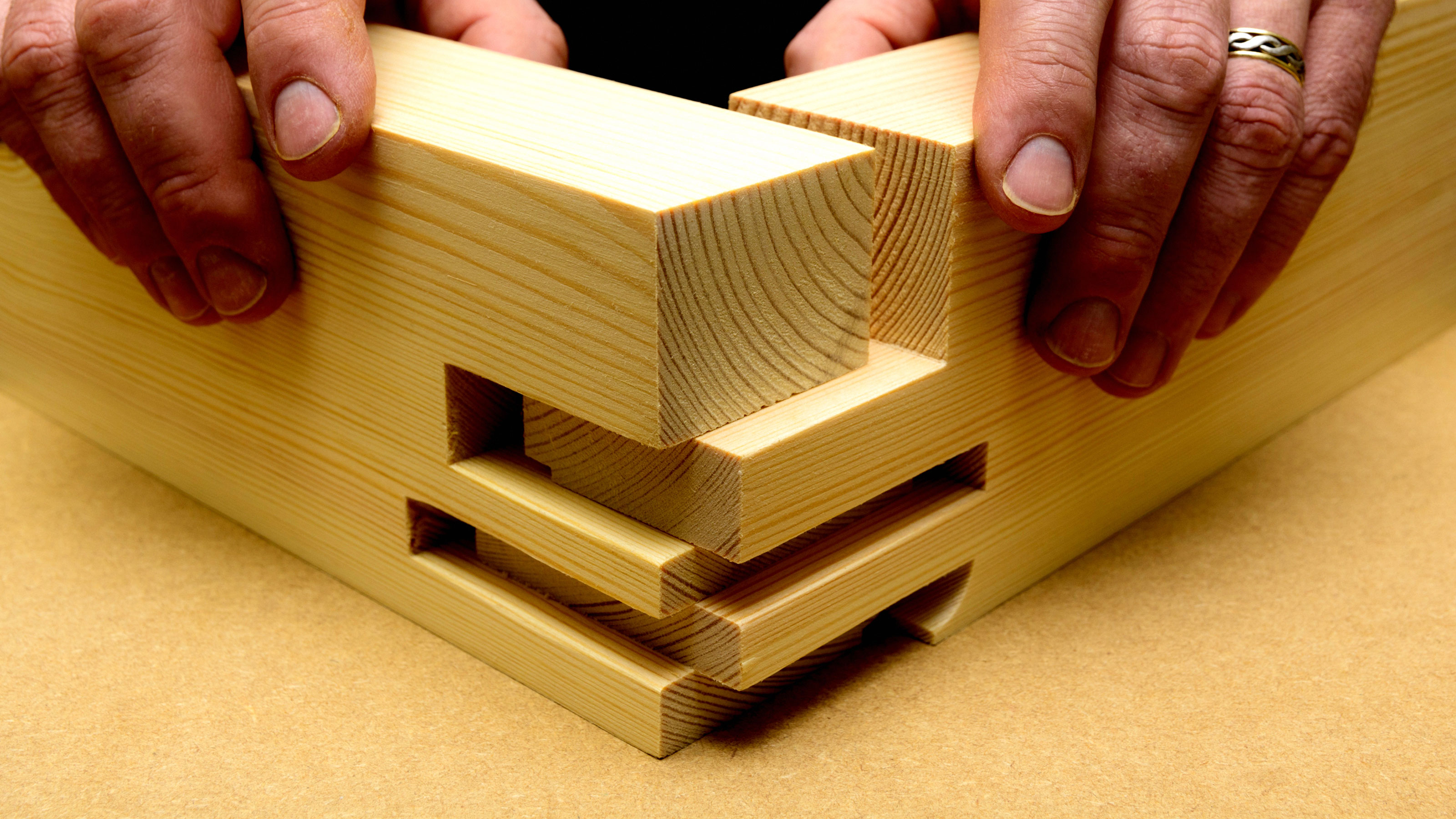

A tenon saw is a specialised saw used by carpenters to create neat, accurate cuts. It gets its name from the mortise and tenon joint that the saw was designed to produce.

Carpenter and small business owner, Scott Godfrey, offers more detail, “A tenon saw is mainly used for making precise, straight cuts in wood, particularly for joinery work. As the name suggests, it’s ideal for cutting tenons – the projecting pieces of wood that fit into mortices.”

He adds, “But it’s also handy for general work that needs clean, accurate lines, like trimming mouldings or cutting small pieces to size. The rigid spine helps keep the blade steady, which is what gives you that control.”

2. What type of saw is a tenon saw?

A tenon saw is a type of back saw and gets its name from the fact that it typically has a brass back. It is one of the larger types of back saw.

The saw plate or blade in a tenon saw is relatively short, typically around 250-300mm and has a depth of around 75mm-100mm. But there are oversized tenon saws available that have greater depths.

The back of the saw dictates how deep the user can cut, because as soon as the back of the saw hits the wood being cut, it cannot go any further. A tenon saw can be used for cutting skirting boards along with a mitre block for neat accurate cuts, but the brass back may restrict the height of skirting board you can cut.

3. What materials can a tenon saw cut?

A tenon saw is typically used for precision cutting, so it is used almost exclusively with wood. Godfrey elaborates, “It’s designed for cutting wood, usually softwood and hardwood. You wouldn’t use it on metal or plastic – it’s really a woodworking tool. It’s not suited for rough cutting or anything where speed matters more than accuracy.”

4. Why does a tenon saw have a brass back?

Unlike reciprocating saws or circular saws (see our guide for circular saw uses), a tenon saw typically has a brass back. However, the back can be made from steel and more rarely wood – but the purpose for a metal or wood back is the same. The back of the tenon saw is there to give the saw blade more rigidity and stiffness, helping to keep it from flexing when in use.

This helps ensure that the blade stays straight when cutting. This in turn gives more accurate – and straight cuts – for a precision finish that is needed when making furniture. The added weight of the back also helps with the cutting motion.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

5. What’s the difference between a tenon saw and dovetail saw?

A tenon saw and dovetail saw are both part of the back saw family along with sash saws. They are both similar in appearance and both have a brass or metal back to help with the accuracy of a cut. A tenon saw is the larger of the two and has a wider and thicker saw blade typically with less teeth than a dovetail saw. The teeth on a tenon saw are crosscut as it is typically used for cutting across the grain.

A dovetail saw – as the name suggests – is specifically designed for cutting dovetail joints, which are generally smaller than tenon joints, hence why they have shorter and thinner saw blades. They have more teeth and rip teeth for cutting along the grain.

6. How many teeth per inch does a tenon saw have?

As a general rule, the more teeth per inch a saw blade has, the finer the cut will be. This, in turn, gives the finished cut a neater finish.

A tenon saw will have around 10-14 TPI (Teeth Per Inch), with 12 or 13 TPI being a popular choice. Godfrey points out, “14 TPI is great for detailed work, while 10 TPI will cut faster but with a rougher finish.” He adds, “What you choose depends on the job, but for joinery, finer teeth tend to give a neater result.”

Other types of saws, such as a dovetail saw, which has around 15-20 TPI. Other saws, such as the best circular saws, have circular blades that commonly have 24 TPI for rough cuts and 80 TPI for finer cuts. In comparison, a standard handsaw typically has 8-10 TPI, as it is used for everyday cuts rather than those that require a neat, smooth cut, such as those found in furniture.

A tenon saw is an excellent choice for cutting skirting boards if you don’t own one of the best mitre saws on the market. Alongside a tenon saw, you need to choose different saws for different projects. Check out our Types of saws guide to help choose the right one for your next project.

Steve Jenkins is a freelance content creator with over two decades of experience working in digital and print and was previously the DIY content editor for Homebuilding & Renovating.

He is a keen DIYer with over 20 years of experience in transforming and renovating the many homes he has lived in. He specialises in painting and decorating, but has a wide range of skills gleaned from working in the building trade for around 10 years and spending time at night school learning how to plaster and plumb.

He has fitted kitchens, tiled bathrooms and kitchens, laid many floors, built partition walls, plastered walls, plumbed in bathrooms, worked on loft conversions and much more. And when he's not sure how to tackle a DIY project he has a wide network of friends – including plumbers, gas engineers, tilers, carpenters, painters and decorators, electricians and builders – in the trade to call upon.