5 circular saw uses that every DIYer should know about to help make sure your next project is a success

A circular saw is a versatile, multi-talented tool that should be a staple in any DIYer's toolbox. Here you can find out how to fulfil its potential and stay safe

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

If you don’t own a circular saw, then you need to seriously think about adding one to your power tool collection. If you rarely use one, you could be missing out on its full potential. Like all good power tools, a circular saw makes your DIY life just that little bit easier.

The best circular saws can power through wood, metal and even masonry if you have the right blade. They are the perfect companion for providing clean, straight edges on sheets of wood, cutting through stud work, fence posts, skirting boards and more.

However, they offer more than just straight cuts. You can set the depth of cut and even the angle of cut to expand its potential. Here, you’ll find five key considerations to look out for to ensure your circular saw is the perfect DIY companion.

Try these circular saws for your DIY projects

Scott Godfrey, with over 20 years of experience in carpentry, joinery, and leading large-scale construction projects, possesses the expertise and practical insights needed to provide authoritative commentary on circular saws in carpentry and construction, making him an ideal expert in the field.

1. Decide between corded and cordless circular saws

Circular saws are typically available in 240V corded versions or cordless battery options, with corded typically being more powerful, as Scott Godfrey, carpenter, explains, "Corded circular saws are more powerful and better suited to tougher, continuous cutting jobs, especially if you’re working with thick timber or sheet materials all day. You don’t have to worry about charging batteries or running out of power mid-cut."

However, the cable can be cumbersome and awkward, getting in the way, especially when working on a construction site or away from a bench.

"Cordless models are far more convenient," continues Godfrey. "Particularly for quick jobs, smaller projects, or if you’re working somewhere without easy access to power. "

Cordless circular saws are available in many different sizes, with the 18v and 36v versions (the 36v model uses 2 x 18v batteries) being most popular.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Godfrey adds, "Most modern cordless saws are powerful enough for general use, and if you already have other tools on the same battery system, it’s a practical choice. For most DIYers or general site work, a cordless model tends to be the more flexible option."

2. Keep both left and right handed circular saws

Now, this may seem like unusual advice, especially considering that some circular saw manufacturers only make one or the other. Still, there are several things to consider when it comes to owning both left and right-handed circular saws.

If you are right-handed, you will (hopefully) hold the saw with your right hand, and you may then choose a right-hand blade so that, from a safety perspective, your other hand does not have to cross over the blade to steady the saw.

It’s not about being left- or right-handed in the traditional sense – it just depends on what feels more comfortable and which side gives you the clearest view when cutting.

Godfrey shares, "You can buy circular saws with the blade on either the left or the right. In the UK, right-side blades are more common, but many right-handed users prefer a left-blade saw because it gives a better view of the cut line."

The left-right argument is prevalent among tradesmen and avid DIY enthusiasts. Still, generally, professionals seem to prefer a left-hand blade, as many of them have been trained on the old worm-drive models, and they are also easier to operate one-handed.

From a safety perspective, especially concerning DIY tips for beginners, it makes sense for a less experienced person to have a right hand blade if they are right handed and a left hand blade if they are left handed, as this will allow the main body of the saw to be closer to them and the blade further away (making it harder for clothes or fingers to get snagged).

However, when cutting large sheets of materials, it may be better to have one rather than the other, depending on which way the sheet is placed, so that the main body of the saw is on the larger surface. This is why it's wise to keep both left and right-hand circular saws in your workshop.

3. Pay attention to your circular saw's dust extract nozzle

It is also important to choose a circular saw that has a dust extract nozzle, so that you can connect it to a dust extractor or vacuum hose.

Thinking about circular saw uses, you should always remember that no matter what DIY project you're working on, the end result is bound to be a tad messy. This is because circular saws themselves are large, high-powered pieces of equipment that generate a lot of dust in their wake.

A dust extract nozzle provides an extra means of minimising the amount of debris left over once you've finished using your circular saw.

When cutting sheet materials such as chipboard, plywood or Medium Density Fibreboard (MDF) the cut produces a lot of dust, and removing this as the cut is made certainly helps with the cleaning process at the end of the task.

4. Do your research circular saw blade sizes

Choosing the right blade size is also important when considering circular saw uses. Standard circular saws are available with blade sizes from 125mm right up to 305mm.

Godfrey shares the popular choices, "Circular saw blades do come in different sizes. The most popular for handheld saws are 165mm and 190mm." He adds, "The size of the blade affects how deep it can cut – larger blades give you more depth, which is useful for bigger timbers or making a clean cut in one pass."

But you might not need a large blade, continues Godfrey, "Smaller blades are lighter and give you a bit more control, which can be handy for finer or overhead work." He adds, "It’s really down to the type of job you’re doing and how often you need that extra cutting depth."

It's worth noting that the blades are also not all the same on circular saws, either, so you need to know what you will be cutting and what you plan on buying at a builders' merchants.

Each blade will have a specific number of teeth, and the more teeth it has, the finer (and neater) the cut. On slower RPM circular saw models, it is better to have more teeth.

5. Adjust like a pro for your circular saw uses

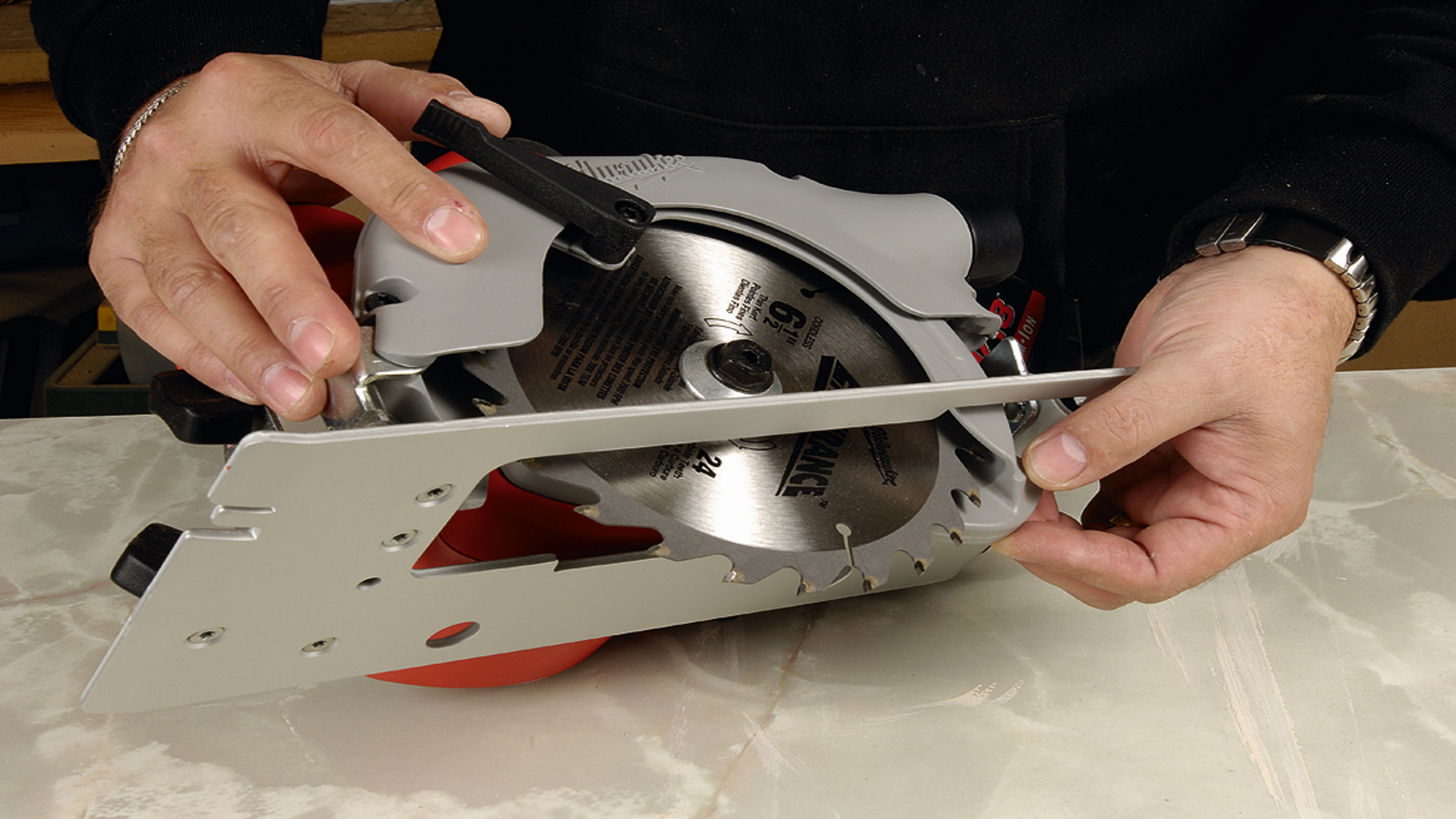

Learning how to effectively adjust the blade of your circular saw will help you achieve that all-important polished cut.

Most circular saws on the market today come with an adjustable edge guide (also known as a fence guide) that rides along the edge of sheet material to hold the saw in a straight (ish) line.

Many manufacturers also have metal rail guides up to about 1.5m long (which can also often be joined together for longer cuts) that get clamped to the materials.

Some circular saws even have slots on the base that then ride along the rail (a bit like a train track) for a very straight and accurate cut.

FAQs

What is a worm drive saw and how does it affect circular saw uses?

The original circular saw tools were known as worm-drive saws. Mainly used on building sites and by professional tradesmen, they usually have their blades on the left hand side of the handle.

A worm-drive is a small gearing mechanism on the saw that allows the motor to be located behind the handle, and power is transferred to the blade via this angled ‘gear’.

On many newer circular saws, however, the motor is located on the side of the tool and the axel of the motor is also attached to the blade as a direct drive.

A worm-drive saw is usually more expensive than the direct-drive versions, and will often have a slightly slower RPM speed, but direct drive circular saws are usually wider than the worm-drive versions.

You will sometimes also have to choose between right or left blade versions.

How can you be safe with your circular saw?

As with all tools, prioritise safety when choosing circular saws. Select the appropriate tool for the task and avoid taking risks. (Remember, when unsure, it is always best to consult a professional.)

If choosing cordless circular saws, ensure to pick from a manufacturer offering a wide range of tools that share the same battery. This way, even with 15 different tools, you won't need 15 separate batteries to finish your project.

A circular saw is a fine addition to any DIYers collection, but you will need other saws as well. Check out our What is a reciprocating saw, What is a mitre saw and What is a plunge saw to help you decide what else you need to add to your collection.

David is a renewables and ventilation installer, with over 35 years experience, and is a long-standing contributor to Homebuilding and Renovating magazine. He is a member of the Gas Safe Register, has a Masters degree in Sustainable Architecture, and is an authority in sustainable building and energy efficiency, with extensive knowledge in building fabrics, heat recovery ventilation, renewables, and also conventional heating systems. He is also a speaker at the Homebuilding & Renovating Show.

Passionate about healthy, efficient homes, he is director of Heat and Energy Ltd. He works with architects, builders, self builders and renovators, and designs and project manages the installation of ventilation and heating systems to achieve the most energy efficient and cost effective outcome for every home.