Learn what a coping saw is and why it’s an essential for your DIY toolkit

A coping saw is the ideal choice for cutting precise shapes in trim and other materials. Discover what other tasks it can handle and what blades are required

Having the right tools to complete a home renovation or DIY project is essential. It simply makes any job easier to complete. Here, you will learn what a coping saw is and discover why it's a necessary addition to your toolbox.

A coping saw is an inexpensive type of saw that performs specific tasks that other saws simply can’t do as well. Here, we take a closer look at the materials it can cut, how to use a coping saw, and which blades you’ll need for different jobs.

Mark has over 20 years of experience in the building sector, leading to a wealth of knowledge surrounding building and renovating that he enjoys sharing with others who are looking to complete their own building projects.

What is a coping saw? A quick definition

A coping saw (like this Faithfull Coping Saw from Amazon) is a type of bow saw commonly used to produce straight, curved, and intricate-shaped cuts in woodwork. It typically has a U-shaped metal frame, a wooden handle and a narrow blade which is held in place via a couple of pins. The handle is also used to tighten the blade, keep it in place and create the proper tension for the job you are working on.

Mark Irving, building expert from Build & Plumb, reveals what it's suitable for, "This type of saw offers more control due to its narrow blade that excels in cutting shapes and curves in decorative features." He adds, "In particular, a coping saw can be used to scribe skirting boards as the flexible, thin blade can create precise cuts to shape one part of the skirting board to fit precisely with the other.”

Try these coping saws and accessories on you DIY project

Why a coping saw is called a coping saw

The coping saw has been used for centuries and derives its name from a carpentry technique called the cope, which is called coping when in use. The method is also known as scribing and involves shaping the end of wood so it fits neatly – and almost seamlessly – into the contours of the wood it is being joined to.

Cope – or coping – is also a technique employed in metalworking, applying the same principles. It is also known as a saddle joint.

Kevin has been in the construction industry for 25 years and handles everything, from the distribution and installation of portable structures to financing and manufacturing. He can speak with authority on every aspect of building.

What a coping saw cuts

A coping saw is commonly used in woodworking to cut intricate curved or rounded shapes. A typical example would be wooden flooring where a plank meets a door frame. It can be used to cut out the shapes of the door jamb, the curves of simple architrave or the intricate patterns of more ornate mouldings.

Scribing skirting boards is another common application. This is where you shape one end of the skirting board so that it fits neatly into a corner against another length of skirting board. This is typically used where mitre joints do not fit together well due to uneven walls.

Kevin Keen, owner of Keen's Buildings, adds, "In restoration work, the control of the blade adapts trim to uneven plaster or out-of-plumb framing, keeping historic character intact." In addition, "It also excels for selective removal between studs or in tight cavities where a powered blade would damage surrounding surfaces"

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

A coping saw with the right blade – one with 24 TPI or similar – can also be used to cut through metals such as aluminium, tin, and copper. A blade with a high TPI is also a good choice for cutting plastics, such as plastic plumbing pipe.

How to use a coping saw

The first step is to install a blade that matches the material being cut. This will differ depending on what coping saw you have. Typically, place one end in the pin and adjust the tension so that when you place the other end of the blade in the other pin, it stays in place but isn’t tight.

Then adjust the tension – usually with the handle – and set the angle to begin. Don’t overtighten the blade; while it needs to be secure, it should also have some flexibility.

Keen points out the importance of tensioning: "Precise tensioning keeps the blade from chattering when you swap to a finer tooth count, ensuring a clean finish." He adds, "Brands such as Bahco and Eclipse combine these details and are trusted in both site install kits and furniture shops."

There is an art to using a coping saw and getting curves right. But set the blade at the right angle for the cut, secure what you are cutting, and follow the pencil guide you've marked out, and all should be good. To achieve a smooth finish, use a sander or sandpaper to smooth out any rough edges.

If you're cutting from the centre of the material or away from the edge, you will need to drill a pilot hole first. Then, remove one end of the blade, place it through the hole, and reattach it, adjusting the tension before you start sawing.

FAQs

Are coping saws hard to use?

Coping saws are relatively simple to use, but its shape and blades can make the process seem a little intimidating. The blades typically have teeth which means that you need to pull back a few times to get a starting point. Once you get going it is pretty much a back and forth motion like most saws.

Are there different types of coping saw blades?

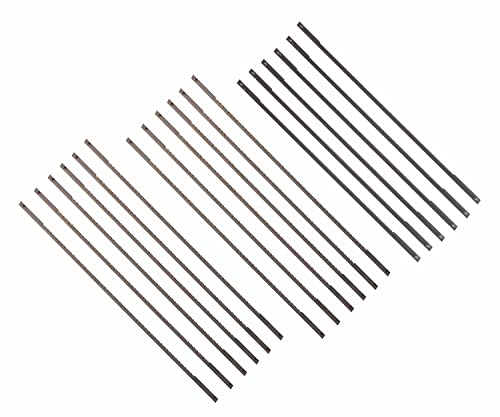

Yes. They generally vary by size, TPI (Teeth Per Inch), and finish. Irving shares more about blades, "Coping saw blades come in a variety of sizes that range in teeth per inch (TPI), often from 5 to 24 TPI. This wide range of sizes offers various types of cuts, with 5 TPI providing a quicker and more aggressive cut, while 24 TPI is slower and more precise. A 24 TPI coping saw is ideal for cutting curves and intricate shapes, with a smooth finish.

The most common type of blade is a steel blade with teeth – like these Eclipse Professional Tools Coping Saw Blades from Amazon – that can be used on wood, metal, and plastic. The number of teeth determines the quality of the finish you achieve. For wood, 15-18 TPI is a common choice for everyday cuts, but if you require a finer finish, you can opt for a 24 TPI blade.

There are specialist wire blades with an abrasive surface – rather than teeth – that can be used for precise cuts on ceramics, making them perfect for tiling a kitchen splashback, a bathroom, or floors.

Now you know how to use a coping saw, find out how to use a circular saw with our 14 tips on how to use a circular saw, 5 circular saw uses, and the best circular saw guides to improve your saw knowledge

Steve Jenkins is a freelance content creator with over two decades of experience working in digital and print and was previously the DIY content editor for Homebuilding & Renovating.

He is a keen DIYer with over 20 years of experience in transforming and renovating the many homes he has lived in. He specialises in painting and decorating, but has a wide range of skills gleaned from working in the building trade for around 10 years and spending time at night school learning how to plaster and plumb.

He has fitted kitchens, tiled bathrooms and kitchens, laid many floors, built partition walls, plastered walls, plumbed in bathrooms, worked on loft conversions and much more. And when he's not sure how to tackle a DIY project he has a wide network of friends – including plumbers, gas engineers, tilers, carpenters, painters and decorators, electricians and builders – in the trade to call upon.