Your complete guide to underfloor heating — including costs

Wondering whether underfloor heating is right for you? Our expert guide is here to answer all your questions and explains how it works, what it costs and how it compares to radiators

Underfloor heating is now one of the most popular ways of heating a home, both for those who are self building, as well as with people extending and renovating their houses. Not only is this an efficient and really effective heating method, but it also adds a sense of luxury — nothing beats that warm underfoot feeling it gives when you kick off your shoes.

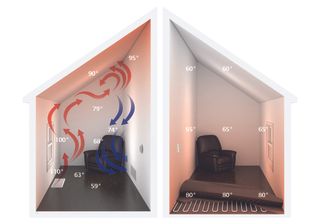

Unlike radiators, which work by heating the air around them through convection, underfloor heating (UFH) uses both convection and radiant heat to warm a space. This combination of heating methods results in a consistent temperature throughout the room — no more cold spots. This can then improved further by the addition of a good underfloor heating thermostat and and well-planned zones.

While the best time to carry out underfloor heating installation is undoubtedly during a self build or when building a new extension, there is no need to rule it out if you were hoping to switch from wall radiators to an underfloor heating system — although it is a little disruptive, it can still be done.

Here, our expert Tim Pullen explains the pros and cons of underfloor heating and takes a look at how different systems work — as well as how much they cost.

How does underfloor heating work?

Underfloor heating installation involves running a system of either pipes or wires underneath the floor of a room. This effectively transforms the entire floor into one huge heat emitter that warms up the space.

Underfloor heating heats from the ground up, which not only results in better comfort levels, but also puts less of a strain on your boiler when compared to traditional radiator systems. This is because of the lower operating temperature (around 40°C) of underfloor heating — radiator systems usually operate at around 65°C.

UFH is actually closer to being a ‘radiator’ than a radiator is. It heats the mass of the floor (the screed and the floor finish) and that heat then (mostly) radiates into the room — there is some convection going on but over 80% of heat transfer is by radiation.

It is also useful to note that underfloor heating is great when used in combination with renewable technology, such as heat pumps, which have a low flow rate.

What types of underfloor heating are there?

There are two main types of underfloor heating:

- Wet underfloor heating

- Electric underfloor heating

In basic terms, a wet underfloor heating system features pipes, filled by warm water. They are often powered by a boiler but underfloor heating with heat pumps is becoming an increasingly popular option. These pipes are typically embedded within a floor screed.

This is the best type of underfloor heating for those building from scratch and/or planning a whole-house system.

Electric underfloor heating is often cheaper and easier to install than wet underfloor heating. However, the running costs can be as much as three times higher.

Are there different types of wet underfloor heating?

There are broadly two types of wet underfloor heating:

- Buried underfloor heating involves placing the pipes into the floor screed. The floor screed is finished, burying the pipes, and the different zones are controlled by the underfloor heating manifold. This is the most efficient wet UFH system, but better suited to extensions and new builds where new floor screeds are required.

- Surface mounted underfloor heating involves specialist systems that install the warm water pipes in insulated panels. They are designed to be low profile, adding just 1.5cm to the floor level, however, this will still cause some issues when retrofitted. These systems tend to be more expensive, too.

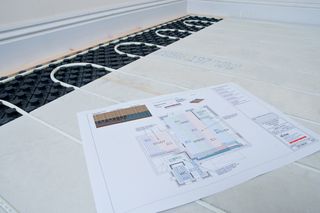

How is underfloor heating installed?

The most common way to install underfloor heating is to lay pipes over insulation and under a screed. Pipes are laid in rows, coiling where necessary, and evenly spaced to ensure an even spread of heat across the floor area. The pipes will be fixed using pipe staples.

A self-levelling screed is then poured over the pipes, effectively burying them. Once poured, the screed is treated with a chemical spray to stabilise and tamped, before being left to dry.

It's a sensible idea to wait four weeks for your screed to dry properly before moving on to laying flooring in your space, but take advice from the supplier for the particular screed mix you're using.

How much does underfloor heating cost?

Wet underfloor heating costs from around £20/m2 to £40/m2 installed, based on a new build or extension. These figures will vary depending on the size of the property, the amount of heating the building needs and whether it is a new build, renovation or conversion. You might expect retrofitting underfloor heating in a renovation project to cost slightly more at around £40/m2 to £60/m2.

This isn't necessarily more expensive than electric underfloor heating systems, and in fact, some of the more advanced electric systems will cost more.

Is underfloor heating more expensive than radiators?

While underfloor heating has a higher initial expenditure than radiators, don't let this put you off. The running costs are generally far lower for UFH than radiators. It's worth noting too that underfloor heating systems have a lifespan of 50 years plus, while the average radiator will only last between 8-12 years before becoming inefficient.

A wet underfloor heating system is estimated to be 25% cheaper to run than radiators when attached to a modern boiler and 40% cheaper when attached to a heat pump. Electric underfloor heating is believed to be around three times more expensive than wet systems as electricity is more expensive.

What is the best way to control underfloor heating?

The majority of underfloor heating system controls feature two main parts:

- A digital zone control that determines the temperature of each room/area

- The underfloor heating manifolds and valves that the zone control operates

The zone control will be placed somewhere where the homeowner can make adjustments, while the underfloor heating manifolds will be placed out of the way – under the stairs or in a cupboard – so as to be unobtrusive.

There is no regular maintenance regime associated with underfloor heating, but if things do go wrong, it will typically be with the heating control systems rather than the system itself.

Can I install underfloor heating into my existing home?

In a new build, the extra cost of underfloor heating relative to the whole build cost is seldom a deal breaker.

However, if you're looking to retrofit underfloor heating in a renovation project, it can be hugely disruptive and expensive as it often involves taking up floors that may otherwise be best left alone, or raising the floor level, which may have implications on the joinery (doors, skirting etc).

Low-profile systems tend to have smaller diameter pipes and run at a higher temperature. This means that the floor will heat up and cool down far more quickly than conventional underfloor heating.

Where underfloor heating is added to an existing radiator system then a different control system will be needed. Luckily, wireless underfloor heating thermostats (some of which can be controlled with a phone app) make installation far easier.

It is often a good idea to install electric underfloor heating in a small, single area like a bathroom or en suite, where it may be difficult to install wet underfloor heating.

It is worth noting that one of the most common — and worst — uses for electric underfloor heating is in a conservatory. Typically these areas need a lot of heat and are used for relatively long periods of the day (compared to a bathroom, for example). This means that running costs become an issue and the extra trouble and expense of a wet system may be well worthwhile.

What are the advantages of underfloor heating?

Underfloor heating holds many advantages over other types of heating system, including radiators. Some of the main pros of UFH include:

- Reduces cold spots across large areas.

- Runs at a lower temperature than radiators, meaning UFH is more energy efficient.

- Compatible with many types of flooring.

- Removes need for space-stealing radiators — underfloor heating increases the available floor area of a house by 15%.

- Safer for children, and better for indoor air quality.

What are the cons of underfloor heating?

Of course there are also downsides of UFH to consider — particularly if you plan to retrofit underfloor heating.

- Underfloor heating is more expensive to install than a comparable radiator system — it typically costs 20% to 50% more.

- Installation time can be longer, especially with wet UFH. Even electric underfloor heating may require work to self level before installation.

- When retrofitting underfloor heating, changes to floor height will need to be considered. This may require extra work in digging out the floor for a level profile.

Is underfloor heating better than radiators?

Potentially yes, but this will be dictated property by property, room by room, depending on heat loss and whether the output from an underfloor heating system is larger than this loss figure.

Radiators are cheaper to buy, they are well understood and there is a huge choice when it comes to size, style and installers, but they are less efficient and take up floor space. Perhaps the biggest problem is that in larger rooms they can produce a temperature difference of up to 4°C across the room.

If we want to set the temperature of the room at 20°C, a radiator system will need to get the ceiling to 21°C or 22°C for us to feel comfortable while watching telly.

With a UFH system, the ceiling can be at 18°C and we will still have a comfortable 20°C at sofa level. According to the Energy Saving Trust, a 1°C reduction in temperature will reduce the heating bill by 10%.

An underfloor heating system also offer a 15% reduction in energy demand compared to a radiator system, which is hard to ignore.

Should I leave underfloor heating on all the time?

With a wet system it can take two or three hours to warm up, so it is better to leave it turned on if you or your family are inside the house and need to keep warm.

To save costs, you can adjust the temperature instead, to make it lower during night time or times when you might not be using the space.

With electric underfloor heating meanwhile, the floor can heat up much quicker. The heating costs depend on how many kilowatts hours (kWh) of electricity you use and this will be more, the longer the heating is turned on or the more watts the underfloor heating uses. For a 125W system turned on for an hour, for example, this will use 1KWh for every eight square metres of electric underfloor heating

How thick should underfloor heating screed be?

The thickness of the floor screed during your installation process will make all the difference. The screed thickness in which the warm wet pipes sit will have a dramatic impact on how the system is used.

A thick screed will give a longer reaction time (the time taken to warm up and cool down), while a thin screed will have a quicker reaction time.

- If the pipes are housed in the concrete floor slab, this should be 150mm thick and give a reaction time of over four hours. In this situation, it is best to run the system all day, at a lower room temperature — say 15°C or 16°C — to provide background heating to the whole house. Highlight heating, such as a log burning stove, is a good idea in the rooms that are occupied

- A standard sand and cement screed would typically be 65mm to 75mm thick and the underfloor heating could take upwards of two hours to heat the room or cool down. This situation may be well-suited to rooms where we spend a lot of time, such as lounge or kitchen, but might be less acceptable in a guest bedroom

- With thinner flow screeds, we might expect a thickness of 35mm to 40mm and a reaction time of around 30 to 40 minutes — the system can be run in a similar way to a radiator system. Flow screeds offer better thermal conductivity than sand and cement, and being thinner and lighter means that they can be suitable for both renovations and new builds

Which is right and best will depend on the construction of the house, your occupation habits and how the underfloor heating system is to be used.

How much does underfloor heating raise floor levels?

Underfloor heating will usually raise the profile of the floor. The amount it is raised by will depend on a number of factors such as how much insulation you need to add, pipe size, and whether you need a screed and floor finish.

There are also some products that get ‘carved’ into an existing screed, in which case there would be no additional build up other than the final floor finish.

If you want to retrofit a wet water system or have concerns about excavating or raising the floor, then low profile systems are a good option. "These have the advantage of coming in different heights and designs which allows them to be installed relatively quickly and easily on most substrates without impacting on the floor to ceiling height of the room," says Mark Dowdeswell, Senior Category Manager at Uponor.

What type of flooring can you use with underfloor heating?

Although underfloor heating with tiles is often the thing that springs to mind for most people looking at what type of flooring to fit, there are many other materials that are also compatible, including wooden flooring and laminate. It can also be used over carpet, although it isn't always as efficient as when laid over a hard flooring. Most retailers will specify whether a flooring will work with underfloor heating, so look for that as your first guide.

Ceramic and porcelain tiles, luxury vinyl tiles and natural stone flooring are among the most efficient choices for UFH.

Concrete is a superb heat conductor, so polished concrete floors work really well with underfloor heating. The thermal mass of your concrete will retain heat and ensure your room stays warm for longer after your heating is switched off than would be the case with a radiator system. They are easy to pour over the pipework and they absorb and hold the heat produced well. Seek the advice of your installer before switching your underfloor heating on though — too soon and it could crack.

It's a good idea to tell the underfloor heating system designer the type of flooring you're using so that the pipe layout can be properly specified

Where should I buy underfloor heating?

Ultimately, the efficiency and success of an underfloor heating system will depend on the quality and design. Choosing a supplier who offers a good design service and aftercare is important. A specialist underfloor heating company is often best placed to achieve this.

If the design is wrong it is unlikely that the homeowner will know until they have lived in the house for a whole heating season — by which time it might be too late.

Finally, if you are choosing to pair underfloor heating with an air source heat pump or ground source heat pump, it is a good idea to choose one supply and install company. Both are complex systems and getting the whole heating system to work in perfect harmony can be tricky.

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Tim is an expert in sustainable building methods and energy efficiency in residential homes and writes on the subject for magazines and national newspapers. He is the author of The Sustainable Building Bible, Simply Sustainable Homes and Anaerobic Digestion - Making Biogas - Making Energy: The Earthscan Expert Guide.

His interest in renewable energy and sustainability was first inspired by visits to the Royal Festival Hall heat pump and the Edmonton heat-from-waste projects. In 1979

this initial burst of enthusiasm lead to him trying (and failing) to build a biogas digester to convert pig manure into fuel, at a Kent oast-house, his first conversion project.

Moving in 2002 to a small-holding in South Wales, providing as it did access to a wider range of natural resources, fanned his enthusiasm for sustainability. He went on to install renewable technology at the property, including biomass boiler and wind turbine.

He formally ran energy efficiency consultancy WeatherWorks and was a speaker and expert at the Homebuilding & Renovating Shows across the country.